The least expensive way to manufacture high volumes of surgical implants is to machine them from near net shape forgings. However, that does not apply to prototypes since the piece price must amortize the cost of the forge tooling over a very small number of units.

As a result, medical device manufacturers are asking suppliers to improve their productivity for implant prototypes by manufacturing directly from bar stock, so that the decision to order forge tooling can be postponed until later in the product development cycle. This allows the medical device company to avoid the tooling costs for low-volume items, as well as products that fail to take off after extensive test marketing.

Thortex Inc., a medical job shop, has benefited from this trend. The company, which was founded in 1990, has approximately 115 people working 16 hours a day, six days a week to manufacture implants (primarily hips, femoral and tibia knee components, and shoulder products) for a number of international leaders in the orthopedic products field. The company has 25 advanced CNC machines including horizontal and vertical 5-axis mills, Y-axis lathes, and Swiss turning machines.

Kerry Smith, engineering manager for Thortex, says getting this equipment to live up to its full potential and keeping the machines fully-utilized is a real challenge. To accomplish this, the company relies on its CAM software – six seats of Mastercam. Smith estimates that the seats are fully occupied during 85% of the company's 96-hour workweek.

Recently, many of the CNC programmers have been making use of the advanced surfacing capabilities of Mastercam X to keep pace with a surge of prototype implants. Smith says, "Our equipment allows us to make complete 3D-modelled prototype implants straight from a raw piece of titanium bar stock, typically with just one setup.

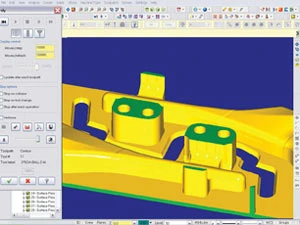

"We use the new roughing and finishing toolpaths in Mastercam X to do this work as efficiently as possible. Basically we take the 3D model of the part and position it where our stock is shown in the Mastercam programming environment. Then the programmer selects a surface, assigns a tool and the desired toolpath, and fills in a few parameters that go with it," continues Smith.

Mastercam's verify function labels the 3D part with colors to provide a fast visual confirmation that all of the areas of the part have been roughed and finished completely and appropriately. The program can then be posted to the machine tool with minor adjustments. Smith believes that these advanced capabilities, coupled with their ease of use, have allowed Thortex to improve CNC manufacturing productivity by about 15%.

Being able to turn work around quickly and produce it efficiently has resulted in more business for Thortex. For example, Smith says, "One of our customers brought in seven different models. They were different types of stems in different sizes. They needed the parts in a little over a month. We were able to provide them with all of those pieces – five of each size – in about three weeks' time from placing the PO. It worked out so well for us that they have since come back and placed a follow up order for another 160 pieces."

During the first six months of 2007, Thortex was able to use its advanced CAM programming capabilities to create 100 new parts. Smith also believes that there are other features in the CAM software that could help the company make further improvements in CNC and manufacturing programming. Heintends to explore these whenever the hectic pace of work allows it.

Explore the March 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025