According to a paper by Nicholas G. Dagalakis, Yongsik Kim, Daniel Sawyer, and Craig Shakarji from the Manufacturing Engineering Laboratory, National Institute of Standards and Technology, in the late '70s, a sensor was invented that could track the movement of an athlete's body parts. In the early '80s, an improved version of this sensor was introduced, by a group of NIST researchers, for the calibration and performance testing of industrial robots. In the late '80s, people experimented with the use of these sensors for human brain operations, and in the early '90s, these sensors were introduced to orthopedic operations. The field of Computer Assisted Orthopaedic Surgery (CAOS) was then born. Although significant progress has been made in the design and use of these sensors for medical applications, there are still sources of accuracy errors that must be addressed.

Today, researchers at the National Institute of Standards and Technology (NIST) are developing state-of-the-art measuring techniques, similar to those used in making aerospace components that precisely fit together, that may soon improve success rates for hip replacement surgery. At the request of a group of prominent orthopedic surgeons and the American Academy of Orthopaedic Surgeons (AAOS), the NIST researchers are working to improve calibrations and operating room testing of the CAOS tracking instruments that surgeons use to plan the delicate and highly complex operation.

To be completely successful, CAOS hip replacement surgery must take into account tiny human skeletal differences. Imprecise measurements – which could result from conditions seemingly unrelated to the surgery, such as operation room noise or temperature – can lead to poor positioning of implants, leaving some former patients with discomfort during walking and, in rare cases, a need to redo the operation.

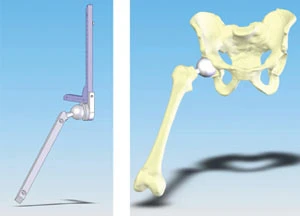

The researchers have built a lightweight device called a "phantom" that resembles the artificial socket, ball, and femur substitutes that surgeons use to replace the joint and bone in hip operations, based on a calibrated X-Y coordinate frame. Because the precise coordinates of the mechanical (magnetic) ball and socket joint's center of rotation have been measured, manufacturers of CAOS tracking sensors can use the phantom to test the accuracy of their measuring instruments. Surgeons also should be able to test the accuracy of their CAOS devices to measure the ball and socket joint's center of rotation coordinates, angles for cuts into the bone, and places for the insertion of screws.

Currently, no standardized approach to the evaluation of CAOS technology exists, but an ASTM International committee is working on the establishment of such standards. In the coming months, NIST will submit its hip CAOS phantom to orthopedic surgeons for review. Clinical trials could follow. If the device wins FDA approval, it can be expected to find its way into operating rooms across the country, and the world. The researchers look forward to extending the application of the technology to surgical procedures on the knee and shoulder.

Explore the March 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025