Do your shoes hurt your feet? Normally a person will shift his or her weight to take the pressure off the sore area. However, in people with diabetes, the nerve endings in the foot often become atrophied, numbing those affected. This can lead to pressure points and wounds that don’t always heal properly. Custom-made insoles by orthopedic shoemakers offer some relief by placing soft material around the injury. Until now, it hasn’t been possible to collect data surrounding insoles – since each insole is a one-off item.

Digitalizing insole manufacturing

Researchers from the German Fraunhofer Institutes for Mechanics of Materials (IWM) and for Environmental, Safety, and Energy Technology (UMSICHT) are collaborating with industry partners on digitalization, with funding from Germany’s Federal Ministry of Education and Research.

“Digital foot mapping is already common practice. As part of this project, we have now also digitalized the insole production process,” says IWM scientist Dr. Tobias Ziegler. “Using newly developed software, the orthopedic shoemaker can design an insole for a patient and print out the result on a 3D printer.”

Advantages of the LAUF project, a German acronym for making customized footwear with laser-assistance, are that mechanical properties of each insole become apparent. Health insurance companies gain valuable data, and insole production costs can be reduced.

A year ago, composites companies Covestro and Lehmann&Voss&Co. laid the foundations for 3D printing insoles. These industry partners were the first to develop a soft material for 3D printing using thermoplastic polyurethane (TPU). Working with UMSICHT experts, they are now developing other types of TPU, expected to be even more suitable for orthopedic insoles.

Accurate rigidity

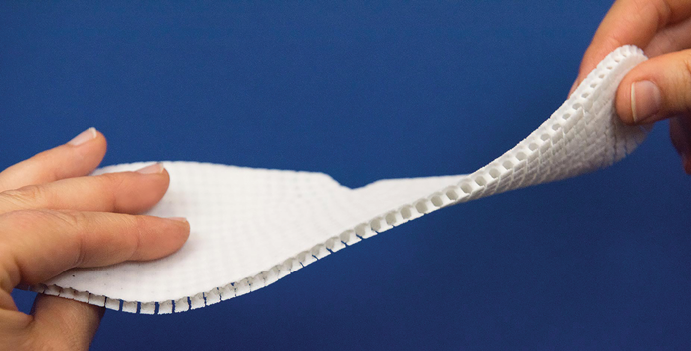

Meanwhile, IWM scientists have been optimizing the 3D structures required of TPU when used for insoles. How soft or rigid insoles are depends on the material and how it is shaped.

“First, we think about structures – straight rods, crooked arms, or triangles, for instance – then we produce a computer model of them, key in the data for material, and simulate how rigid the result is under pressure,” Ziegler explains. “By altering the structure type, we can determine the insole rigidity.”

The IWM team uses application-oriented load simulations to resolve which structures are needed and where. They test the material’s load-bearing strength and expected lifespan.

He also uses this approach in relation to other materials and structures for 3D printing. Data relating to different insoles is next sent to Fraunhofer IWM’s industrial partners rpm - rapid product manufacturing GmbH and Sintermask. The company’s 3D printers print them via selective laser sintering. Another partner, Explius, is responsible for processing the 3D data. Fraunhofer UMSICHT is responsible for optimizing and testing the printing process. Once an insole has been printed, Fraunhofer IWM tests points of failure using tensile, abrasion, and bending.

In a few years, IWM scientists hope this software will be available to orthopedic technicians through IETEC, a member of the project.

Fraunhofer UMSICHT

www.umsicht.fraunhofer.de

LAUF project partners include Fraunhofer Institute for Mechanics of Materials IWM; Fraunhofer Institute for Environmental, Safety, and Energy Technology UMSICHT; IETEC Orthopädische Einlagen GmbH Produktions KG; Covestro AG; Lehmann&Voss&Co. KG; rpm - rapid product manufacturing GmbH; Sintermask GmbH; and Explius GmbH.

Explore the May 2017 Issue

Check out more from this issue and find you next story to read.

Latest from Today's Medical Developments

- Lumetric's Scanning Tubing Measurement System

- Latest advancements in machine tool technology

- Visit Okuma America at IMTS 2024

- March 2024 USMTO orders were $354.7 million

- AM for Aircraft Cockpit Interior Components

- Arizona WearTech Center member receives new patent

- SABIC showcased progress in plastic innovation

- Ink for 3D-printing flexible devices, no mechanical joints