ExOne

The ExOne Company and the University of Pittsburgh developed reusable metal filters that fit into a specially designed respirator cartridge for sustainable, long-term protection against contaminants, such as COVID-19.

ExOne’s binder jetting technology is a high-speed form of 3D printing that can produce metal parts with specific porosity levels that can effectively filter out contaminants while allowing airflow.

ExOne has 3D printed respirator filters in two metals – copper and 316L stainless steel – and a range of porosity levels for use inside a unique cartridge designed by the Mechanical Engineering & Materials Science department in Pitt’s Swanson School of Engineering. Initial testing for airflow and filtration efficiency is currently underway, and the filters are being optimized with the goal of adhering to an N95 respirator standard.

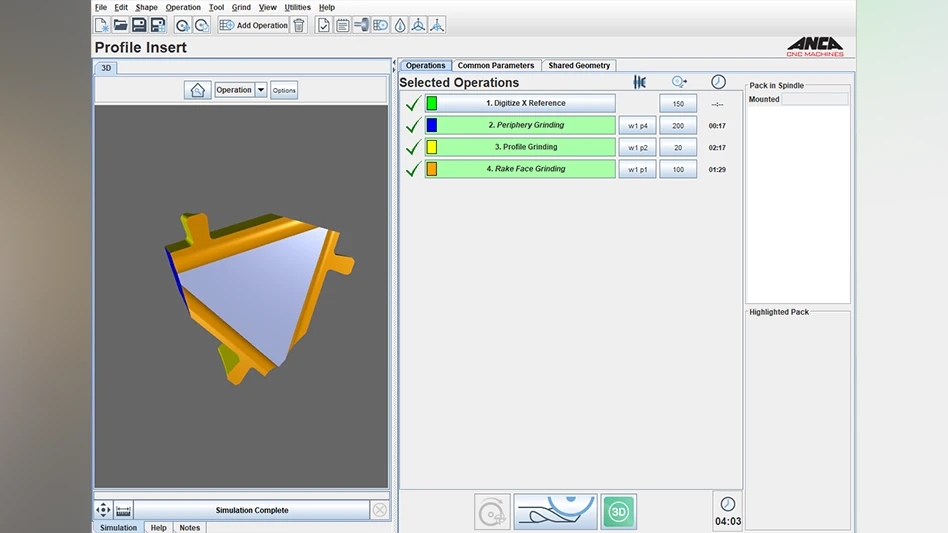

3DP metal filters

ExOne’s binder jetting technology uses an industrial printhead to selectively deposit a liquid binder onto a thin layer of powdered material, layer by layer, until a final object is formed. After 3D printing powdered metals, the object is then sintered in a furnace to dial in a specific level of porosity. While binder jetted metal is typically sintered to full density, some applications require a specific level of porosity, such as filters.

Associate Professor of Mechanical Engineering and Materials Science at the Swanson School, Dr. Markus Chmielus, and his research group is using CT scanners to analyze the microstructure and porosity of the filters. Ansys is providing additional computer simulation support to analyze and optimize the performance of the filters.

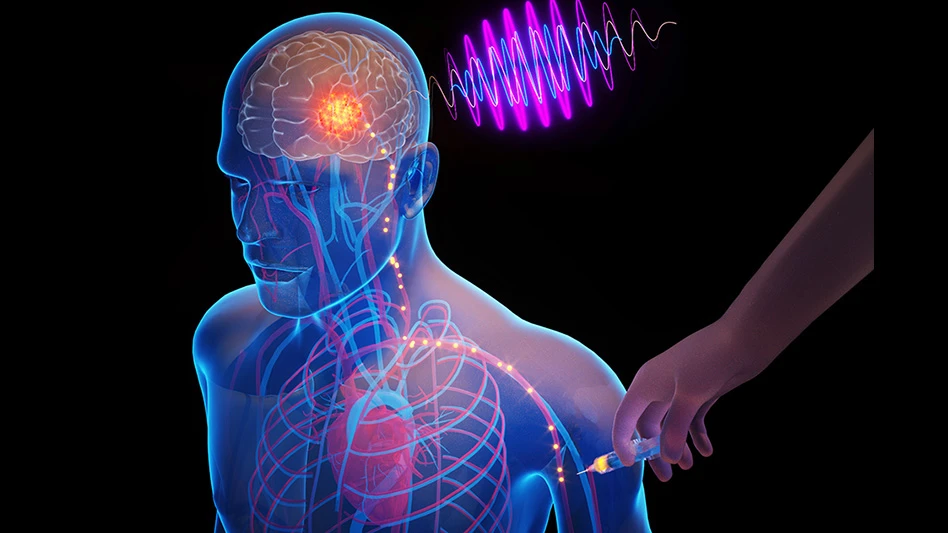

While copper and stainless steel filters are currently being tested, copper has been known to have antibacterial properties since ancient times. The first recorded use of copper to kill germs was in the Edwin Smith Papyrus, the oldest known medical document in history, according to the Smithsonian. Many studies have proven copper’s disinfectant powers. One landmark 2015 study, funded by the Department of Defense, revealed that copper alloys contributed to a 58% reduction in infections. COVID-19 research also suggests the virus dies faster on copper than on other surfaces.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.