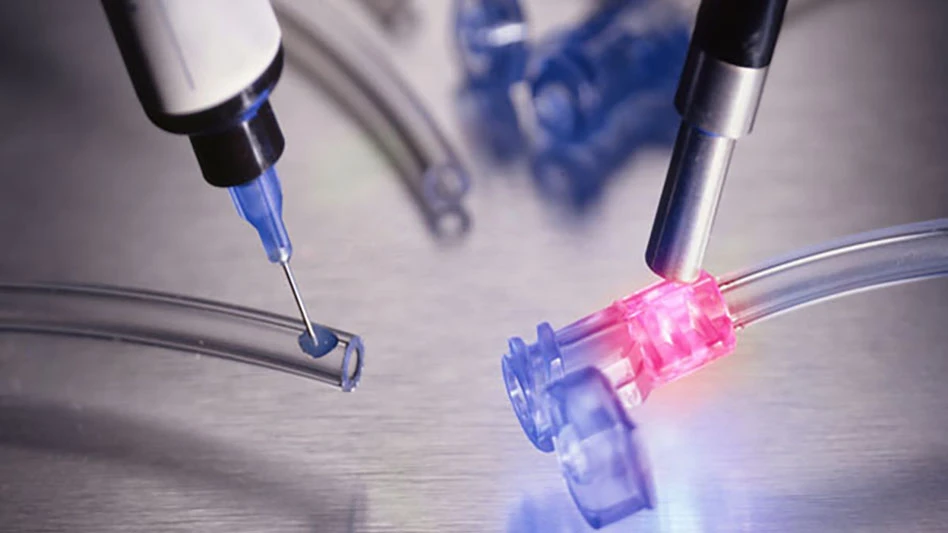

PHOTO: METHODS MACHINE TOOLS

The MH 320A horizontal machining center uses a PC2 automatic pallet changer (APC) with 12.6" (320mm) pallets to lower cycle times and increase throughput.

The MH 320A’s work envelope measures 16.9" (430mm) in diameter by 18.7" (457mm) in height and can handle workloads up to 551 lb (250kg).

The BIG-PLUS 40 taper direct-drive spindle ensures tool longevity and optimal part finish. Also included is a Fanuc 0iMF control and 40-tool automatic tool changer (ATC).

Methods Machine Tools Inc.

https://www.methodsmachine.com

Explore the April 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- US metalworking machinery orders through November 2025 reveal 17.8% increase from first 11 months of 2024

- Precision metering pumps for medical device manufacturing

- #81 Manufacturing Matters - Additive Manufacturing Analysis, Trends, Forecasts with Terry Wohlers

- Velosity opens precision development center to accelerate medical device product launch

- A look at the latest in the defense industry

- EMCO manufacturing showroom offers customers hands-on milling, machining engagement

- Workholding Roundtable to feature expert insights on a booming market

- Ilika, Cirtec advance strategic partnership to commercial level