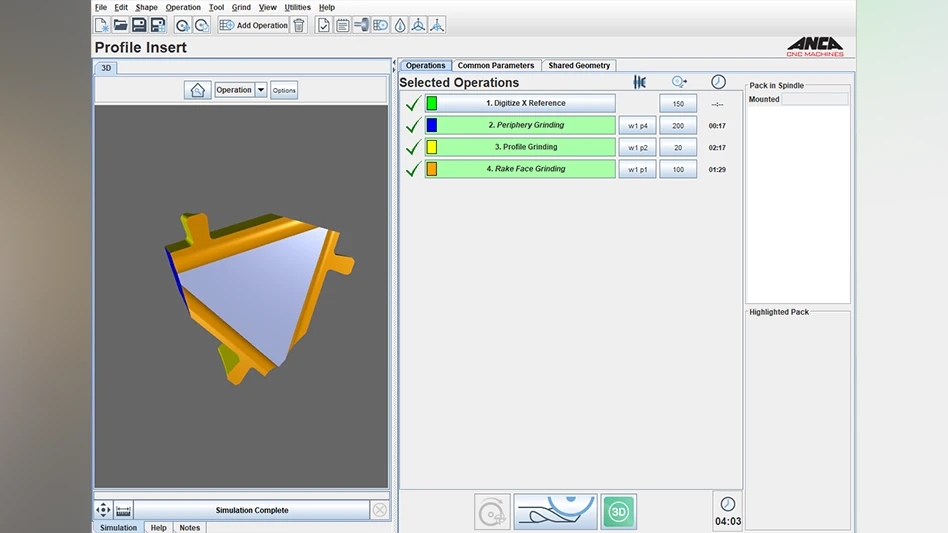

Materialise has partnered with HCL Technologies to develop a platform that provides increased integration for hybrid manufacturing. With this collaboration, CAMWorks software from HCL will be powered by Materialise AM technology to facilitate the production of metal parts, combining the benefits of additive manufacturing (AM) freedom of design with the speed and accuracy of CNC machining. The partnership also represents the first initiative to provide an integrated CAD/CAM solution for hybrid manufacturing in a Solidworks environment.

Hybrid manufacturing is a technology that bridges the benefits of subtractive and additive processes to produce parts of complex design and close tolerance. The integration of AM and computer aided manufacturing (CAM) software in one platform will facilitate the traceability of the production process while saving redundant manual work. Users of the new CAMWorks AM module powered by Materialise, will be able to create support structures directly in CAMWorks and interface with the main metal printers via the Materialise Build Processor.

“The market space and applicability of the additive manufacturing technology has been growing dramatically in the past 5 years. Integration with current manufacturing systems is the next step to unlock digital transformations in manufacturing,” says Stefaan Motte, vice president of software at Materialise. “This requires in-depth understanding of both subtractive and additive processes. We are certain that companies adopting hybrid manufacturing will benefit greatly from this collaboration, which combines our 30 years of experience in AM with the CAM expertise of HCL.”

GH Rao, president of Engineering and R&D Services (ERS) at HCL Technologies says, “We are very excited with the new partnership and the potential hybrid manufacturing offers to the future of computer-aided design and manufacturing. By combining advanced integrated CAM technology from HCL with the innovative 3D printing technology from Materialise, we look forward to enabling companies to create innovative products which can be brought to the market faster and at a lower cost.”

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

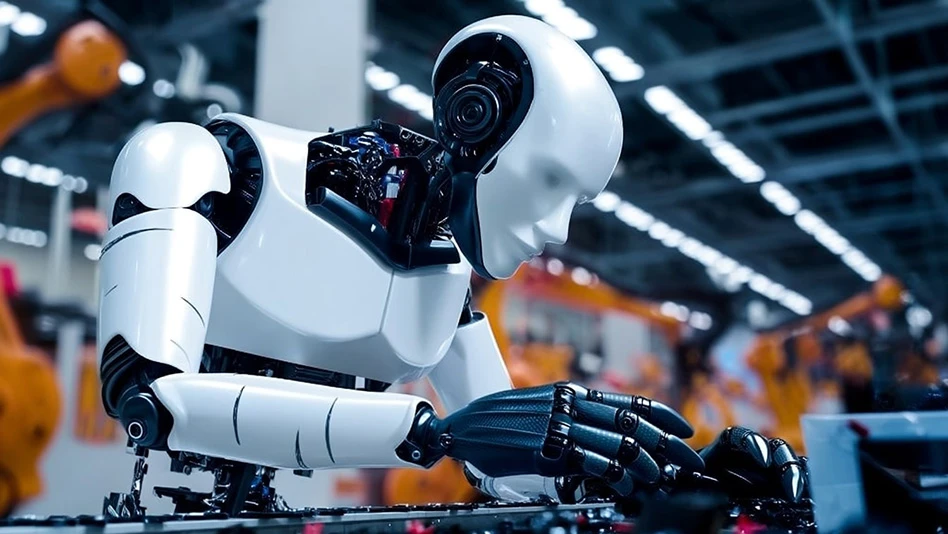

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

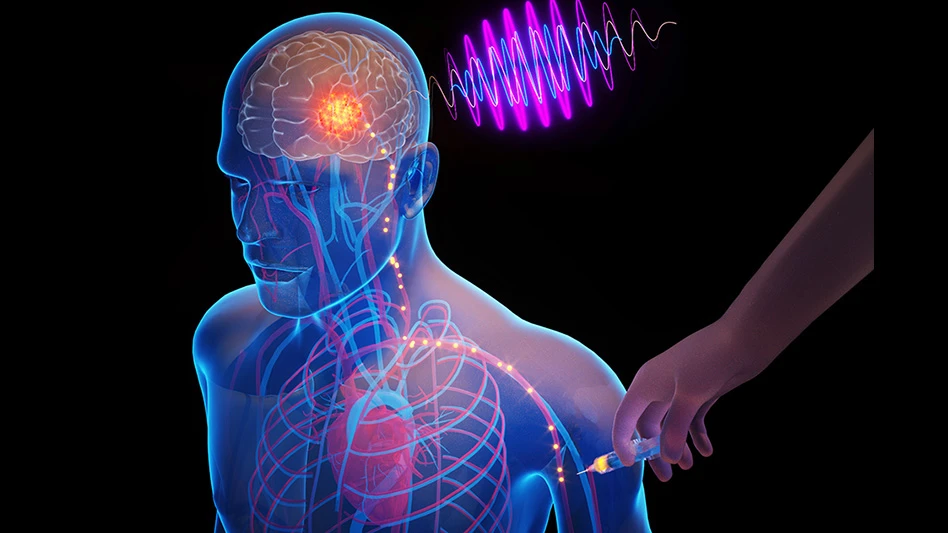

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.