GIE Media’s Manufacturing Group

About the presentation

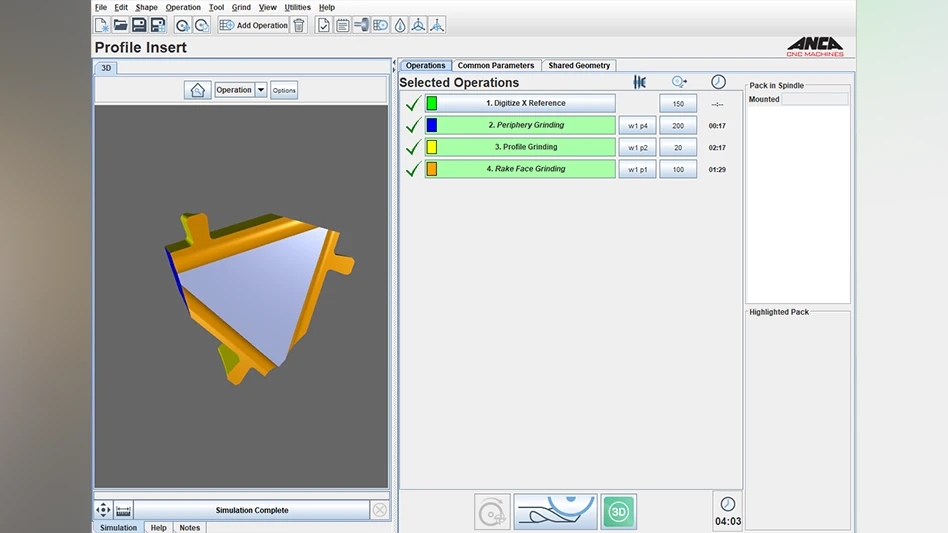

Additive manufacturing and the digital aspect of Industry 4.0 have found their ways to the cutting tool industry sector, and the results add up to significant gains for today’s metalworking shops. As key to the digital future of machining, advanced monitoring and control systems continuously record signals from the machine tool that are generated during part production. Shops then use this data to monitor and adjust the machining/tooling parameters to achieve process optimization.

As it does for other industries, additive manufacturing/3D metal printing allows cutting tool OEMs to generate tool and cutter designs and geometries that up until now were impossible to produce using conventional manufacturing methods. In his presentation, Mr. Blosser shows how this newly acquired revolutionary design and build freedom has led to several innovations and improvements that enhance overall tool and cutter performance. Some of these include special internal cooling channels that boost cutting speeds while extending tool life and that promote minimum quantity lubrication for cost savings as well; advanced geometries for higher cutting parameters in today’s challenging materials; lighter weight cutter bodies that are easier on machine tool changers yet still provide the same maximum cutting strength; and many other such never-before-possible innovations.

Registration

Powered by AMT and managed by GIE Media, The IMTS 2022 Conference features 69 different sessions you won’t want to miss so register today. Focused on a range of topics that include process innovation, plant operations, quality/inspection, and automation, The IMTS 2022 Conference addresses improving productivity; improving part quality; and developing a stable, competent workforce to lower the cost of manufacturing in the United States and create new levels of market demand.

Meet your presenter

Mark Blosser has held a variety of technical and leadership positions during his near 40 years in manufacturing. He steadily built a career starting at KOMET as a sales engineer before becoming regional manager, director of solution business, VP of engineering and applications, and Detroit operations manager. In his current position as CERATIZIT’s executive director of technology and solutions, sales and applications, supporting the automotive industry, Blosser oversees projects that help customers optimize and streamline their operations. He holds a computer science degree from St. Petersburg College and a machine tool technology degree from Pinellas Technical College.

About the company

The CERATIZIT Group is a manufacturer of hard material products for wear protection and cutting tools, developing, producing, and marketing an array of cutting and wear-protection products based on hard metals, cermets, or technical ceramics, from powders to (semi-)finished tools and coated components. The products include hard metal rods and reformed blanks for milling and drilling tools, blanks for printed circuit boards, blades, dies and die blanks for metal cutting and punching, nozzles, hobs, and milling rollers. The company holds more than 1,000 patents worldwide.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.