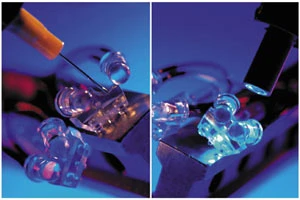

The DYMAX 3000 series plastic-bonding adhesives make highspeed, high-volume bonding of plastic appliances, subcomponents, housings and enclosures possible. These adhesives cure in seconds upon exposure to ultraviolet light and/or visible light, even through UV-blocked plastics. These no-VOC, worker-friendly adhesives from DYMAX form high-strength, environmentally-resistant bonds to plastics and other substrates including polycarbonate, PVC, phenolic, acrylic, metal, glass and ceramic. They are exceptional adhesives for bonding dissimilar materials, something that cannot be done with traditional welding methods and other types of adhesives.

These plastic-bonding adhesives are compatible with the new DYMAX BlueWave LED (Light Emitting Diodes) visible light, high-intensity spot curing system. The BlueWave LED spot curing offers many advantages over traditional UV spot curing systems including no bulbs to change, cool cures, no warmup and constant intensity for thousands of hours. The BlueWave LED generates light using an array of surface-mount LEDs instead of traditional metal halide or mercury bulbs. The LEDs produce exvisible light energy in a relatively narrow wavelength band centered at 410nm, as contrasted to a typical broad-band, high-pressure UV bulb (300nm to 500nm). This system emits a maximum visible light intensity output of more than 2,500mW/cm2 from an 8mm diameter lightguide, and allows users to adjust intensity output from 0% to 100%. The relatively narrow band produced by LEDs generates cooler curing temperatures. The BlueWave LED is excellent for curing gaskets and adhesives designed to bond to polycarbonate, PVC, PET, metal, glass and many other substrates.

Explore the January February 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025