Key benefits of coatings in medical devices

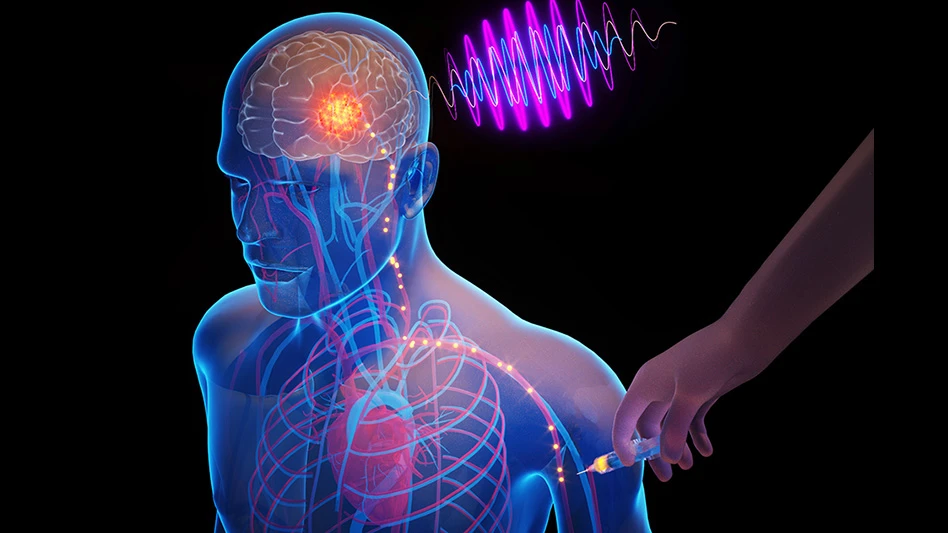

Enhance device functionality

Extend product lifespan

Improve patient outcomes

Reduce friction, patient discomfort

Applied to devices such as needles, guidewires, catheters

Reduce resistance during device insertion

Lessen pain during procedures

Speed recovery and reduce tissue damage

Deliver wear resistance for longer device life

Applied to components, surgical tools

Bond permanently for durability

Offer low friction, non-stick, flexible

Extend lifespan, lower replacement costs

Expanding device & component applications

Metal substrates

Guidewires, needles, mandrels, coils, hypotubes, cables, etc.

Stainless steel alloys, tungsten, titanium, nitinol, etc.

Silicone and rubber

Catheters, O-rings, seals/gaskets, cannulas, tubing, valves, etc.

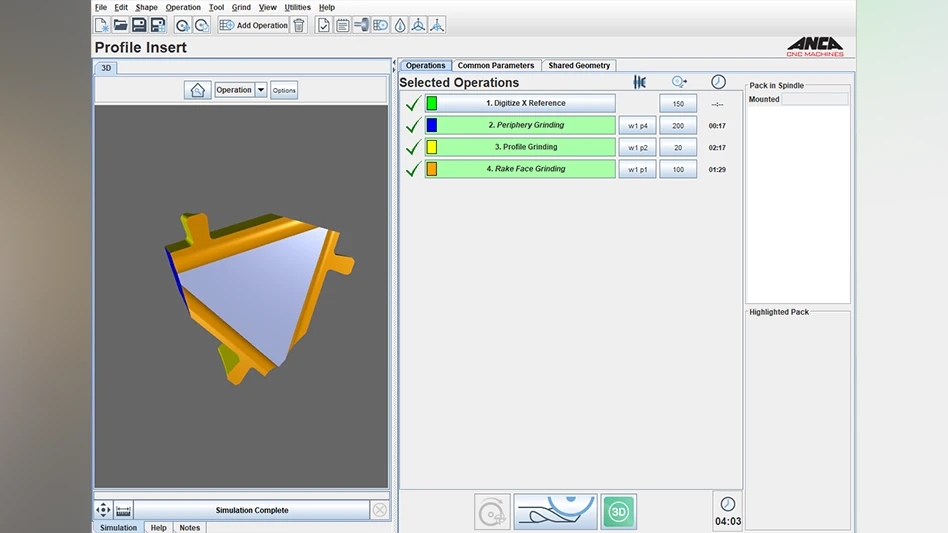

The science behind coatings

Application techniques – Electrostatic spraying, dip coating, ultra-thin film

Coating technologies – PTFE, ceramic, silicone; Water-, solvent-, powder-based; Biocompatible, PFOA-free, PFOS-Free

The future of medical device coatings

PFAS-free coatings – Sustainable, compliant alternatives to traditional PTFE

Custom formulations – Wider variety of options for new product designs

Impact of innovative coatings

Transforming devices – Improve performance, safety, longevity

Better healthcare – Lead to improved patient outcomes

Source: Surface Solutions Group – https://surfacesolutionsgroup.com/

Explore the July 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Robot orders accelerate in Q3

- Pro Shrink TubeChiller makes shrink-fit tool holding safer, easier

- Revolutionizing biocompatibility: The role of amnion in next-generation medical devices

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.