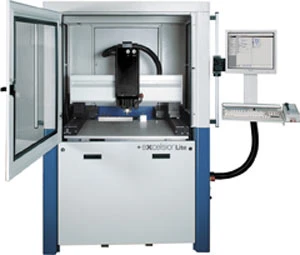

Datron's excelsior Lite was designed specifically for manufacturers who need their innovative high-speed technology, but for budget reasons are unable to afford a machining center made exclusively for small tooling. The excelsior Lite has an aluminum bed rather than the granite table found on its big brother, the excelsior EX. While this does impact rigidity to some extent, this may not be critical to every application, particularly small medical parts.

The excelsior Lite comes standard with a 1.2kW; 30,000rpm spindle; 20 in. x 20 in. machining area; 5-tool Automatic Tool Changer; Windows-based 3D control software; C3 1GHz PC with 256 MB RAM; 15 in. CRT; keyboard and controller; Ethernet, CD-ROM & USB ports; remote monitoring capability; enclosure with safety lock-out; and a 6-month limited warranty (workmanship and materials).

The excelsior Lite's large machining table and full enclosure feature a solid steel base. This combination delivers both safety and stability. X, Y and Z agility is facilitated by virtue of a hand-held controller, which is included as a standard feature. The excelsior Lite, like all other Datron machines, has a precision ball screw for superior accuracy. Drives are covered and protected from chips and debris, resulting in the ability to machine metal with minimized vibration and maximized accuracy.

The excelsior Lite's compact design, protected precision ball screws, and 30,000rpm spindle gives it the durability and speed to machine non-ferrous metals. The high rpm rate evacuates chips and the heat associated with them from the cutting channel, resulting in lower machining forces and less vibration.

Explore the July 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables