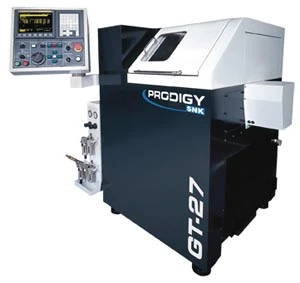

SNK's Prodigy GT-27 gang tool lathe features a standard C-axis spindle, a polymer base and precision components for fast and accurate small parts turning. The machine spindle reaches speeds up to 6,000 rpm.

The GT-27 lathe uses three axes of motion that can be commanded in absolute or incremental modes. The C-axis spindle allows for indexing and positioning, as well as the more advanced functions of interpolation and polar coordinate milling.

Precision and versatility are achieved through incorporating non-heat generating collet closers, the absence of a turret and full C-axis indexing positioning. In addition, the Prodigy GT-27 can index in 0.01° increments, resulting in live tooling being used for side drilling and milling operations, easily performing simple and complex operations. The GE Fanuc Controller also contributes to the ease of operation, as well as faster and more responsive performance with the inclusion of brushless digital servo drives.

The GT-27 is designed and built for primary and secondary machining operations in a variety of applications, including medical, commercial, ceramics, and fasteners. Maximum production bar work is up to 0.6875-in. in diameter.

Explore the November December 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Gore completes acquisition of Conformal Medical

- Medical textiles designed for cardiovascular, orthopedic, dental prosthetic applications

- Micro-precision 3D printing: Trends and breakthroughs in medical device manufacturing

- One-component, dual-cure adhesive system for medical device assembly

- #82 Manufacturing Matters - Forecasting 2026 with GIE Media's Manufacturing Group

- Flexing prosthetic finger offers lifelike appearance and movement

- How the fast-evolving defense market impacts suppliers

- Medtronic’s Hugo robotic-assisted surgery system makes US debut