Plan to attend The IMTS 2018 Conferences to gain deeper insights into new manufacturing technologies and ideas!

About the topic

In the aerospace industry, the slightest design improvement can have a staggering impact on the efficiency of flight, which is why aerospace manufacturers dedicate tremendous time and talent to advanced engineering. Metro Aerospace has an ingenious microvane product design which delivers small 3D-printed modifications to the exterior of cargo aircraft to reduce drag and improve fuel consumption by 4%.

Invention of the part was only the tip of the iceberg. The final SLS 3D-printed microvanes by Metro Aerospace had to meet all of the rigorous standards outlined by the engineers who designed them, as well as undergo a First Article Inspection Report (FAIR) with thorough documentation, to prove traceability for FAA regulations.

Registration is now open, so check out the IMTS 2018 website for more information.

Traceability, reliability, and repeatability are the core requirements of any mass manufacturing process. During this presentation, Leslie Peters will address the rigorous process Metro Aerospace undertook with its partner, 3D Systems, to efficiently move the microvanes from prototyping to production and deliver this new product in the highly regulated aerospace industry. Jim Davidson will highlight some of the advanced solutions used to streamline the inspection and reporting processes.

Meet your presenters

Jim Davidson is an operations manager for 3D Systems’ On-Demand Manufacturing in Tulsa, Okahoma. In this role, he is responsible for daily parts production to meet customers’ prototyping and low volume production needs using SLS, DMP, and CNC processes. Prior to joining 3D Systems, Jim was with Laser Reproductions in Gahanna, Ohio. The company was acquired by 3D Systems in August 2014.

As CEO of Metro Aerospace, Leslie Peters brings more than 30 years of executive leadership structuring and executing mission critical business strategies in global marketplaces. She combines operational excellence with sales leadership, for small and large organizations, developing controls to improve profitability and increase revenue while maintaining strong customer relationships.

Peters’ career has centered on industries including automotive and aerospace, where she built strategic relationships with customers such as GE, UTC, Rolls-Royce, Lockheed Martin, Volkswagen, Daimler, and Ford Motor Co.

Latest from Today's Medical Developments

- US metalworking machinery orders through November 2025 reveal 17.8% increase from first 11 months of 2024

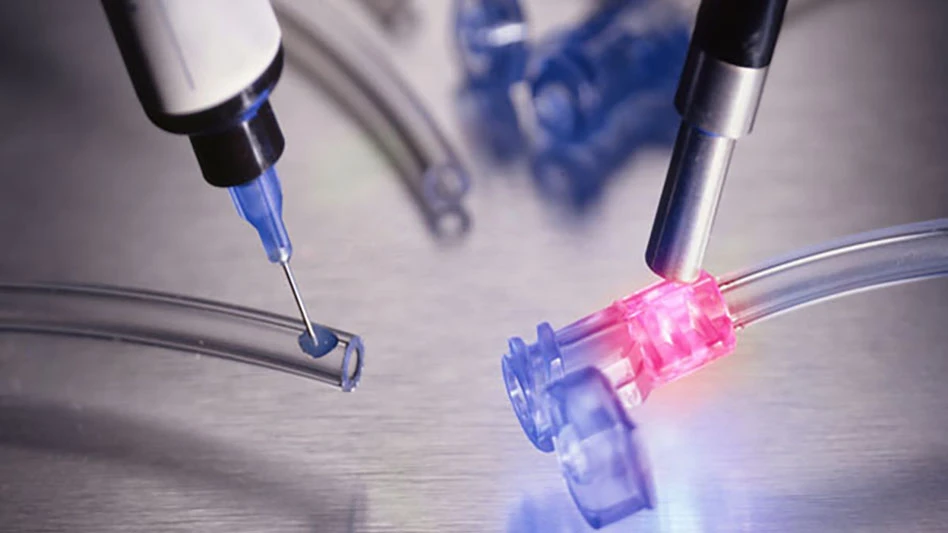

- Precision metering pumps for medical device manufacturing

- #81 Manufacturing Matters - Additive Manufacturing Analysis, Trends, Forecasts with Terry Wohlers

- Velosity opens precision development center to accelerate medical device product launch

- A look at the latest in the defense industry

- EMCO manufacturing showroom offers customers hands-on milling, machining engagement

- Workholding Roundtable to feature expert insights on a booming market

- Ilika, Cirtec advance strategic partnership to commercial level