LexaGene - Exothermic Molding

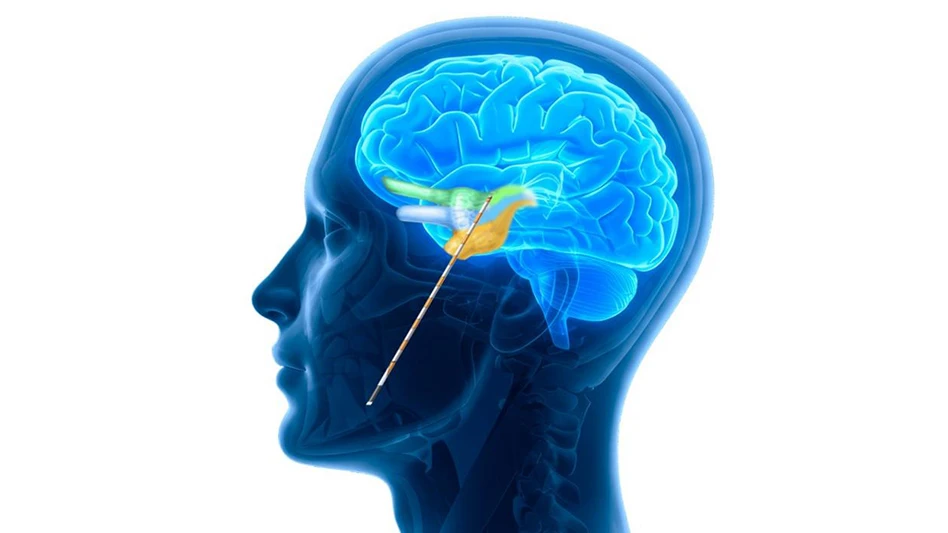

LexaGene, a manufacturer of medical testing equipment, has hired Exothermic Molding Inc. to help in complete its MiQLab, a genetic analyzer. Officials at LexaGene describes the machine’s advantages of purifying and analyzing genetic material, testing for 27 targets simultaneously, delivering results in about an hour to a computer or mobile device, and offering one button operation.

Exothermic’s Production Manager Jorge Perez remarked that the MiQLab is the perfect complement to our portfolio of client products. Exothermic has been producing parts for specialized medical testing equipment for years. He further indicates how Exothermic was chosen for the project and the company’s role in helping LexaGene complete the product roll-out.

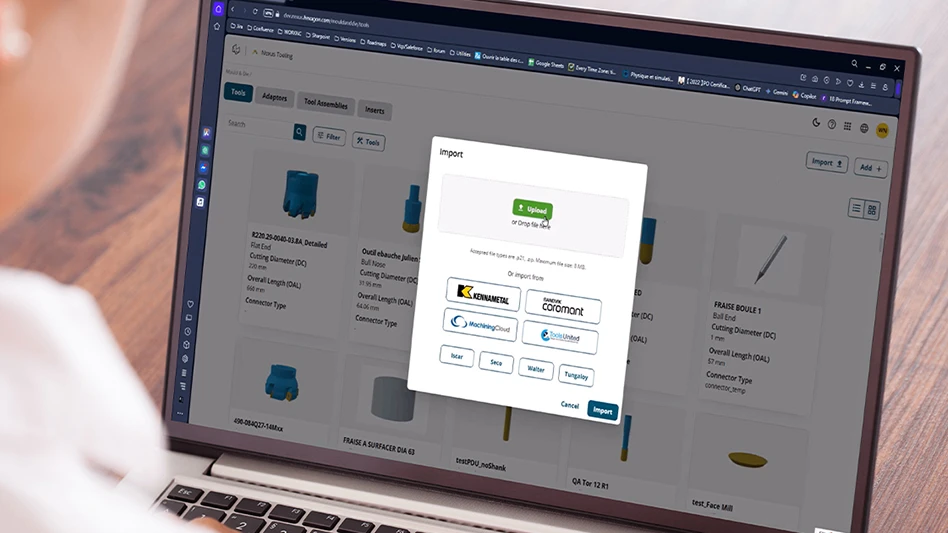

“LexaGene supplied us with aluminum parts for their prototypes of The MiQLab that required CNC machining, silk screening with specialized colors, and skilled painting capability. The assembled prototypes were slated for shipment to a photo shoot and to a show with extremely tight deadlines. Exothermic’s Assistant Production Manager James Patnaude shepherded this project through in record time. We had to take the finishing operations from concept to delivery in just three days. We had to ship the job out as soon as the paint dried. Patnaude had the courier service standing by and the product was delivered from our New Jersey plant to LexaGene’s CEO at his home on a Saturday,” Perez says.

Founded in 1971, Exothermic Molding, Inc. has remained a family-owned privately held business. The company is known for both its innovative use of manufacturing processes and materials. The first known adopter of Reaction Injection Molding (RIM), Exothermic has taken that process a giant step further with the advent of a Nobel Prize winning polymer known as Proxima.

According to Exothermic’s management, Proxima has unique and superior properties over other polymers, such as its high durability and lighter weight. The company has torture tested the material with excellent results – driving over it with a vehicle and even attacking it with a sledgehammer. Neither test showed any damage. Proxima’s lighter weight can help reduce shipping costs, as well.

Latest from Today's Medical Developments

- How permanent magnets are powering medical innovation

- Forecasting the year ahead in design and manufacturing

- Tecomet, Orchid Orthopedic Solutions announce merger agreement

- Resonetics acquires manufacturing assets, process IP from Med-Ally

- Trelleborg’s medical device solutions highlighted at MD&M West

- Arterex expands medical device design, manufacturing platform with Synecco acquisition

- Medical-grade thermoplastic resin

- #58 Lunch + Learn Podcast with LANG Technik & Metalcraft Automation Group