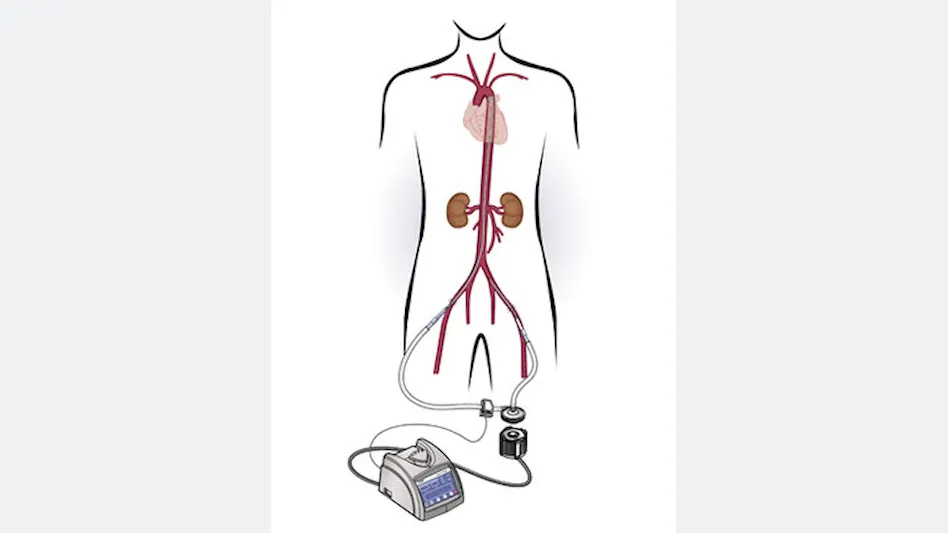

For patients suffering from congestive heart failure, Orqis Medical Corporation's Cancion System offers an investigation method to supplement the heart in performing its job of pumping blood to the body. Makrolon 2558 polycarbonate resin from Bayer Material Science LLC (BMS) is used for molding multiple components of the Cancion System, which serves to minimize damage to fragile blood cells and to reduce clotting as the device augments blood through the patient's descending aorta.

The Cancion System, currently being evaluated in the pivotal MOMENTUM clinical trial, provides continuous aortic flow augmentation using an innovative, new centrifugal pump and proprietary catheters to create a supplemental circuit that takes pressure off of the heart. The company calls this a "rest-to-recovery" treatment for acutely decompensated congestive heart failure patients who do not respond adequately to standard medical therapy. By alleviating the heart from some of its work, Orqis hopes to show that the heart can grow stronger, allowing patients to feel better, leave the hospital, and remain out of the hospital.

Connectors used where the catheters enter the femoral arteries.

When the Cancion System is used, catheters are inserted into the patient's femoral arteries, drawing blood out through the left artery and into the pump, which propels it back into the body via a longer catheter. The longer catheter enters the right artery and extends up through the descending artery where it terminates with a Uturn near the aorta, discharging blood back into the normal flow.

Makrolon polycarbonate was selected by Orqis Medical for the critical catheter connectors because of its biocompatibility, robustness and clarity. These same attributes led Levitronix LLC to choose Makrolon polycarbonate for its CentriMag Blood Pump, a key component of the Orqis system.

Makrolon 2558 polycarbonate is an easy-flow polycarbonate resin with outstanding impact strength and ductility, excellent electrical properties, and dimensional stability. Certain color formations have met the requirements of the FDA-modified ISO 10993, Part 1 "Biological Evaluation of Medical Devices" tests. Biocompatibility and durability of Makrolon polycarbonate are critical to the applications.

"Most catheters are intended for short-duration, single-use injections," says Robert Pecor, senior R&D engineer for Orqis, explaining why Makrolon polycarbonate was selected for the connectors. "Unlike the Cancion System, very few are designed for long-term use with blood continuously flowing through them."

The unique CentriMag blood pump from Levitronix uses magnetic levitation to create a frictionless environment that does not damage blood.

"We have to be very careful to minimize the potential for thrombosis, or damage to the blood cells," Pecor says. With that in mind, the Makrolon polycarbonate connectors were designed to create smooth joints between the urethane catheters and the PVC tubing used in the system. Pecor credits Bayer's engineering support with helping refine the injection molding process, assuring proper flow, and establishing better processing parameters for the connectors, which are molded by Advanced Technology. "We're very pleased with the material. It's clear and robust, and we get a consistently high-quality product that works exactly as intended," says Pecor.

At the heart of the system is the CentriMag centrifugal pump, which uses magnetic levitation to create the fluid dynamics necessary for circulatory support applications. The pump is assembled from four Makrolon polycarbonate parts and a magnet. The magnet is encased in two white polycarbonate components, creating the pump's impeller. The impeller floats inside a clear polycarbonate housing, made of two parts bonded together to form a chamber with a top inlet orifice and a side discharge outlet. This pump is placed inside a unique motor receptacle with no moving parts. The motor uses electromagnetic forces to levitate and rotate the impeller within the pump chamber.

The CentriMag blood pump is capable of generating blood flow rates as high as 9.9 l/minute with a lower limit of flow of 400 ml/minute required by neonatal cases. Use of magnetic levitation eliminates shafts, seals, bearings and heat-generating friction, minimizing the risk of hemolysis and thrombus deposition. The efficient design of the pump accommodates the low flow rates that are required by the Cancion System without blood stasis occurring. "It's gentle on blood," states Kurt Dasse, Ph.D, chief executive officer of Makrolon polycarbonate pellets, which are melted down and injection molded to form parts like the catheters. Levitronix.

Makrolon polycarbonate pellets, which are melted down and injection molded to form parts like the catheters.

The CentriMag pumps are injection molded and robotically assembled in a cleanroom environment, and the chambers are bonded with a UV-curable adhesive. "We picked this material because it is known for being biocompatible. We put it through many batteries of tests to demonstrate that it didn't cause thrombosis and that it could be used for the intended duration," says Dasse. The Makrolon polycarbonate is "fantastic" because of its clarity and biocompatibility, according to Dasse, who added that Bayer's technical support group was very instrumental in helping Levitronix bring the pump to fruition.

Explore the May 2007 Issue

Check out more from this issue and find you next story to read.

Latest from Today's Medical Developments

- UCIMU: Q1 2024, a downturn in the orders of machine tools

- #43 Manufacturing Matters - 2024 Spring Aerospace Industry Outlook with Richard Aboulafia

- Tsugami America’s Technical Center in Minnesota

- RobOps Copilot for AI-powered robot optimization

- US companies invest heavily in robots

- #34 Lunch + Learn Podcast - Cobots' potential to revolutionize aerospace manufacturing with Techman Robots

- Universal Robots announces seamless integration with Siemens PLCs

- This month's Manufacturing Lunch + Learn is May 16