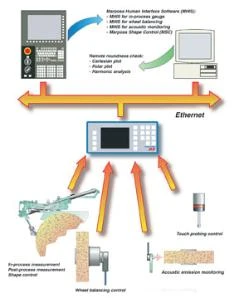

Medical parts manufacturing demands process control. The P7 multi-function electronic process-control device manages various types of machine tools using pre-process, in-process, and post-process measurement, shape, and touch-probe controls. Its ethernet-based networking capability provides a connection that replaces serial connections for fast, reliable data transmission between devices and the P7 unit.

According to its manufacturer, an ethernet connection simplifies integrating the P7 with PCs, which eliminates having to use a serial-port connection. Also with the ethernet connection, the P7 easily interfaces with networks. This lets medical shops connect the P7 to the Internet for off-sight process monitoring and analysis.

In addition, the system manages automatic grinding-wheel balancing as well as optimizes wheel feed and dressing cycles through acoustic analysis.

Marposs Corp.

Auburn Hills, Mich.

marposs.com

Explore the March 2005 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025