The e-Zassi.com subscriber base continues to expand as the medical device industry recognizes the actionable benefits of how the patent pending software platform is addressing the challenges of technology transfer. Peter von Dyck, CEO of e-Zassi, attributes the growth in adoption of the company’s products and services to its ability to empower the industry as it contends with the confusion regarding healthcare reforms, the growing capitalization gap and the many issues concerning tech transfer intellectual property rights and industry collaboration. e-Zassi software:

- Allows organizations to harvest more new technologies from their researchers, and reduces the chance for intellectual property leakage

- Increases their ability to rapidly triage larger numbers of innovations and make better decisions about which technologies currently have the greatest commercial appeal

- Expands the reach of marketing for subscribers who are seeking to engage in licensing agreements for new medical device technologies

- Empowers individuals to collaborate, search and be matched with synergistic industry partners

About e-Zassi.com

e-Zassi.com is a provider of web-based Business Process Improvement (BPI) software that enhances business development and technology transfer of medical devices. It is simple to use, more cost effective than traditional methods and protects all parties from confidentiality risks delivering immediate competitive advantages. For additional information call 866.874.6328 or visit www.e-zassi.com.

Latest from Today's Medical Developments

- US metalworking machinery orders through November 2025 reveal 17.8% increase from first 11 months of 2024

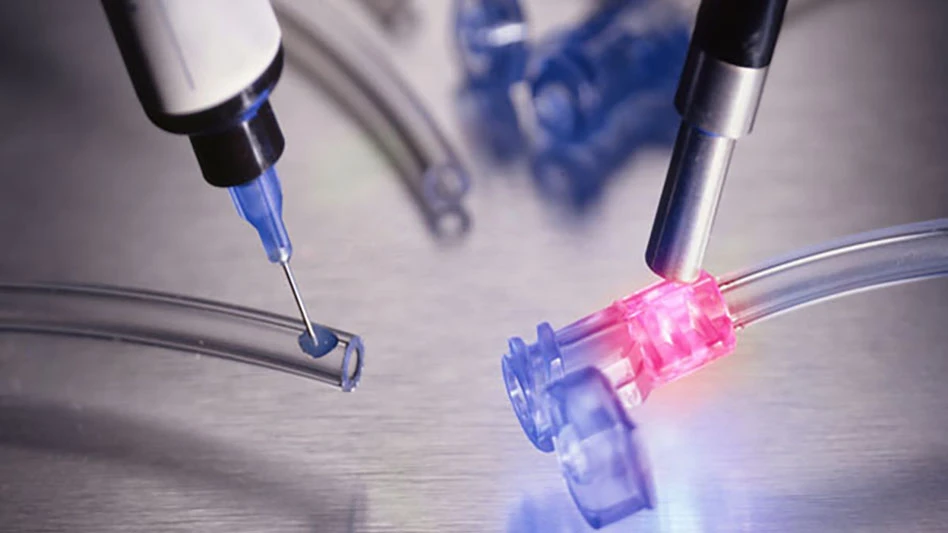

- Precision metering pumps for medical device manufacturing

- #81 Manufacturing Matters - Additive Manufacturing Analysis, Trends, Forecasts with Terry Wohlers

- Velosity opens precision development center to accelerate medical device product launch

- A look at the latest in the defense industry

- EMCO manufacturing showroom offers customers hands-on milling, machining engagement

- Workholding Roundtable to feature expert insights on a booming market

- Ilika, Cirtec advance strategic partnership to commercial level