Editor's Note: This article originally appeared in the September 2025 print edition of Today's Medical Developments under the headline “Medical manufacturers take a shine to high energy finishing”.

If you were one of the many children who had a rock tumbler growing up, you may remember the fascination of putting rough stones inside the small machine then removing them a few days later to find shiny, polished gems. Today, rock tumblers are still considered valuable STEM (science, technology, engineering, and math) tools as well as fun toys to get kids away from screens for a while.

Those rock-tumbling enthusiast children (and adults!) may experience some déjà vu if they end up in a manufacturing career. Most manufactured components require finishing of some kind, and if you walk into the Minnesota facility of Mass Finishing Inc. (MFI), you’ll find yourself looking at what are essentially giant rock tumblers – only they’re faster, more powerful, and instead of rocks, they’re cleaning, deburring, and polishing industrial components.

MFI offers vibratory finishing equipment – a reliable method for finishing parts – but it’s most well-known for its high energy centrifugal barrel tumblers. The speed at which these machines run, and the resulting gravitational force they produce, can achieve super-smooth mirror finishes in as little as five to 10 minutes. With lower energy finishing methods, such as deburring wheels or belt sanders, these results can take hours or days.

“Our centrifugal barrel tumblers, when they’re spinning at full speed – some more than 200rpm – can apply 12g to 13g on the tumbling media and the parts,” says Cole Mathisen, sales and marketing manager at MFI. “If you compare that with your traditional kind of rock tumbler style or vibratory equipment, which are 1g to 1.5g, the surface finishes you can achieve are significantly different with high energy.”

Isotropic implants

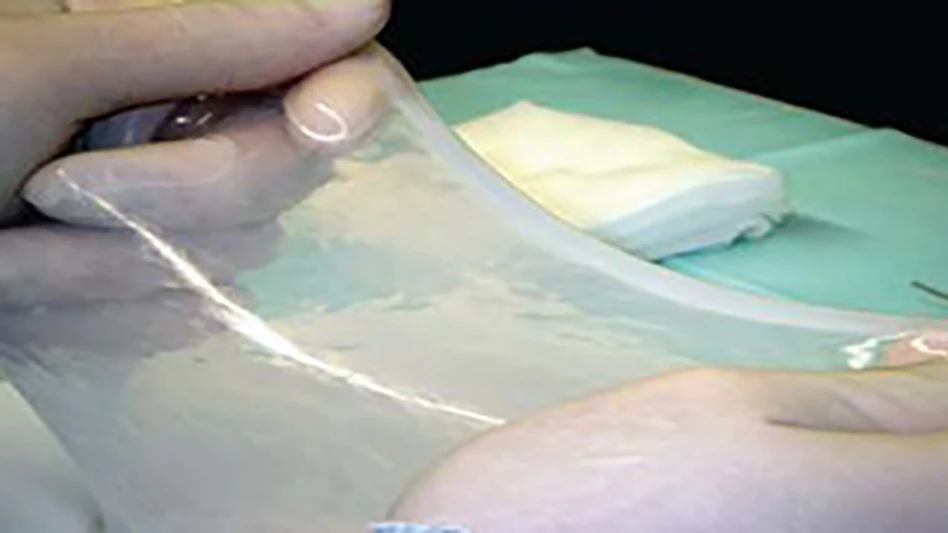

Tumblers can produce isotropic finishes, which are perfectly smooth without the directional lines created by alternative finishing methods such as sanding. That’s a critical element in many orthopedic implants, particularly articulating parts such as knee replacements.

“The big benefit of having an isotropic finish on those orthopedic parts is you’re less likely to have infection due to things like plaque buildup,” Mathisen continues. “A rougher surface will invite a lot more bacteria to grow.”

In some cases, a manufacturer may require smooth and rough surfaces on a single part – for example, a rougher surface facilitates bone growth, so MFI will mask that area to keep it untouched by the finishing process.

MFI finishes a wide range of medtech components in addition to orthopedic implants, such as stents, heart valves, catheter tubes, and surgical instruments, in various materials including most metals as well as some polymers. Because of the diversity of finishing requirements, the company’s centrifugal barrel tumblers are available in multiple sizes ranging from 12L to 330L, though the most popular for medical components is the 40L tumbler.

Regardless of its size, each tumbler has four work chambers rotating like a Ferris wheel, creating a waveform allowing the parts to freely tumble and giving them full finishing coverage. Those chambers can then be further divided so a larger part, such as a knee, can have its own space to keep it from knocking into other parts and causing chipping.

MFI’s largest tumblers can finish thousands of parts per week, and often the company will have machines in multiple sizes running simultaneously for different steps of the finishing process. A simple, small part, such as a bone screw manufactured on a Swiss lathe, typically only needs a final polish that can be completed within a few minutes. A 3D-printed implant, on the other hand, often requires three steps: the first using a rough, abrasive grinding media to even out layer lines, followed by a smoothing pre-polish, then a final polish using non-abrasive porcelain or dry corn cob media.

Media coverage

Finishing media is the other part of the equation. It’s not a matter of simply loading parts into a tumbler and pressing start; you need some kind of rough material to buff those surfaces, and selecting the right media for each step of the process is a complex decision. MFI offers an extensive portfolio of finishing media to meet the requirements of varied parts and finishing stages, including porcelains and plastics as well as sustainable corn cob and walnut-based media. Those materials are then available in different sizes, shapes, weights, and compositions.

“Media choice is dependent on the material,” Mathisen says. “Titanium is harder than the aluminums, but it’s light, so we might need to use a more aggressive media. So the hardness of the part, and then the geometry of the part, then the starting surface roughness, those are all things that go into selecting the media, and then just individual features of the part. If there are holes or crevices or spots where you don’t want the media to go, or spots you do want the media to get into, that’ll determine what your size and shape is going to be.”

MFI makes its own treated corn cob media, producing almost 700,000 lb per year. This includes a blend specially formulated for medical components, without stearic acid or animal fats.

The only time MFI typically uses a dry finishing process, including just the finishing media without an additional water and soap compound, is for the final polishing stage using corn cob media. The more abrasive media such as plastic and ceramic, used for deburring or smoothing, is optimized by a wet finishing process, for which MFI offers various liquid compounds.

“There isn’t a lot of formal documentation about tumble finishing,” Mathisen says. “In some cases, it’s kind of like a black magic to some people where they don’t really understand how the tumbling media and everything works. What we try to help people with is they don’t have to be a mad scientist – we have a full lab here at our facility, different size machines and hundreds of different media that we can test.”

Consistency is key

While MFI counts multiple industries among its clients, about 20% to 25% percent of those clients are from the medical industry, according to Mathisen. For medical components, the average process time from raw part to full polish is about 30 to 90 minutes. In addition to time and cost savings, high energy finishing offers consistency that’s difficult to achieve when finishing parts by hand.

“If you compare a customer that’s doing parts individually, one at a time, there’s a lot of room for variation between different operators or different times of the day if that operator is hand polishing or hand blasting parts,” Mathisen says. “So if you can get a tumble process dialed in that works, you’re guaranteeing a lot more consistency with your parts.”

Mass Finishing Inc.

https://massfin.com

Explore the September 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- IMTS 2026 runs Sept. 14-19 at McCormick Place in Chicago, Illinois

- Master Bond’s MasterSil 800Med

- ZEISS celebrates 100 years of advancing innovation in the US

- Teleflex sells acute care and urology businesses for $2.03 billion

- HANNOVER MESSE: Where research and manufacturing meet

- What’s next for the design and manufacturing industry in 2026?

- Arcline to sell Medical Manufacturing Technologies to Perimeter Solutions

- Decline in German machine tool orders bottoming out