Schneeberger

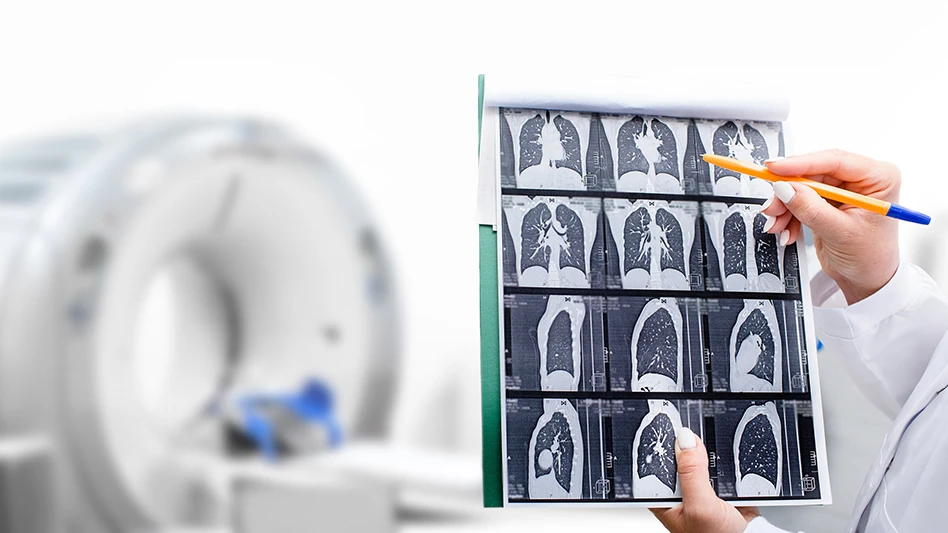

Facing ongoing competitive pressures and market growth demands, life science and biomedical original equipment manufacturers (OEMs) must constantly deliver new advancements in technology, processes, workflows, and production. But in addition to pursuing improvements that focus on expanding success, OEMs must also ensure against the in-use failures of their advanced equipment.

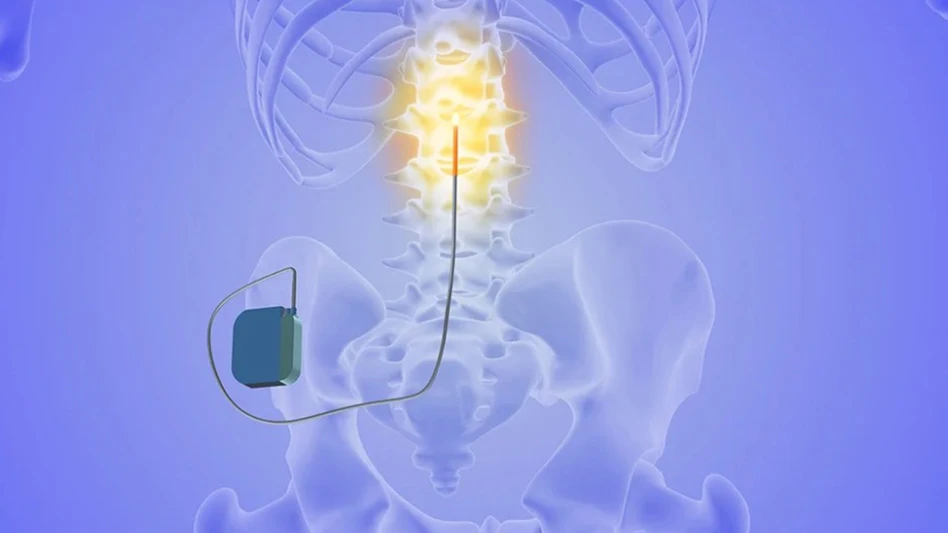

In the case of advanced instruments used in research, scientific, medical, and other critical applications, neglecting improvements and safeguards in one seemingly minor component – in-process linear motion systems – can generate consequences ranging from inconvenient to catastrophic.

This white paper highlights how next-generation linear motion systems can be specified, designed, installed, and maintained to both advance life science and biomedical capital equipment manufacturing – and ensure against failures of any consequence.

Latest from Today's Medical Developments

- OSSIO opens US headquarters in Florida

- Punch-laser combination machines enable precision cutting of sensitive materials

- Enlil, Interlynk to develop integrated cybersecurity solution for medical device manufacturers

- Mastercam releases second 2026 installment in new semi-annual software update cycle

- Medtronic plans to expand interventional cardiology portfolio with CathWorks acquisition

- Nikon releases latest update to dimensional measurement software

- US cutting tool orders reach $206.1 million in November 2025

- Greenland is a vital link in the global supply chain