Shops grinding orthopedic implants and medical rotary cutting tools require close cooperation with customers, most of which use computer modeling to design their parts.

Machine tools that quickly and accurately translate these generated models into finished product are a must. Which is why Anca incorporates the power of Unigraphics 3Dmodeling software to develop total grindingmachine packages in short leadtimes from initial concept to finished solution.

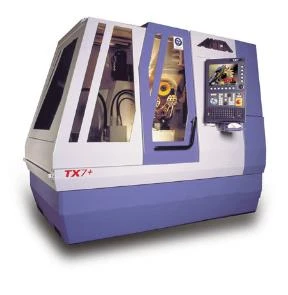

With extensive experience in medicalimplants grinding, Anca owns all core competencies of the design, manufacture, assembly, sales, and support of its CNC grinding machines. This includes mechanical, electrical, and electronic designs, along with system and applicationsoftware development.

The company's machines are wellsuited for extremely precise and heavyduty grinding. They feature directdrive spindles, rotary and linear axes, polymer concrete bases, and CNC and servodrive technology specifically for grinding applications.

Typical medical parts ground on Anca machines include knee joints and bone rasps, and with advanced software, the machines simulate the grinding paths for such parts prior to actual production.

Anca Inc.

Wixom, Mich.

anca.com

Circle 56

Explore the March 2005 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025