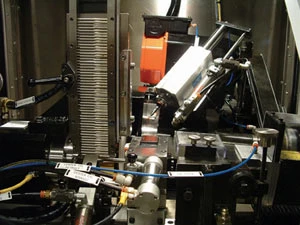

Equipped for production thread grinding of parts from 1mm to10mm diameter, Drake's GS:TEM "MINI" thread grinder is designed for higher volume, precision threaded parts manufacturers. The Drake MINI is now available with linear motor or ballscrew axes, as well as with a robot loader utilizing pallets. A pallet changer enables the machine to run unattended for three shifts. Customers can also opt for the original rocker-style magazine loader. If you're grinding small taps, Drake's forming and cutting tap software, small diameter wheel (200mm) and low-mass wheel axis provide intricate control over the shape of a form tap's lobes and relief. Drake also provides multi-rib rolls for form or cut taps with topping and chamfer features.

In combination, these features give this little grinder its big volume capability. For example, a recently shipped MINI was able to grind and chamfer 1/4-20 ANSI taps to a 2.0Cpk in less than 58 seconds including time to probe for the cutting edge.

In addition to taps, the Drake MINI excels at grinding thread rolls, thread gages, worms, ballscrews, e-steering components, aerospace fasteners and surgical bone screws. It's also equipped with a diamond roll contour dresser for dressing complex topping and non-topping wheel forms including: full radius and gothic arch, acme with crest and root radii or chamfers, as well as 60°, Whitworth, ISO, buttress and other thread forms.

IMTS BOOTH B-7407

Drake Manufacturing

Warren, OH

drakemfg.com

Explore the August 2008 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables