Niagara Cutter designs, engineers, and manufactures precision tooling for a range of industrial applications. Traditionally, such tooling includes solidcarbide, cobalt, and highspeedsteel end mills available in standard and proprietary configurations and performanceenhancing coatings. However, a recently developed product line expands the companys tool offerings for electronics, aerospace, and medical industries.

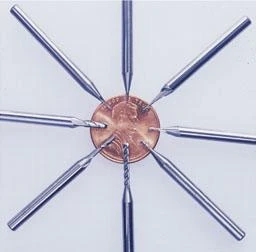

The new line of microdecimal end mills range in size from 0.005 to 0.120 in. and come in two and fourflute, square, and ballend configurations. Besides these tools, the company is continually expanding its medicalpartsmachining products, two of which are Stabilizer cutters and CVD polycrystallinediamondcoated end mills.

Stabilizer cutters sport asymmetrical flute designs that reduce chatter causing harmonics. The coated end mills enhance tool life and performance for machining abrasive materials such as graphite, hardcarbon, highsilicon aluminum, and plastics.

For one medicalcomponents manufacturer, a Niagara crystallinediamondcoated fourflute ball end mill successfully machined an aluminumoxide/silicondioxidecoated aluminum part with a hardness of 60 Rc. Finish milling the part eliminated a grinding process that was expensive and difficult to set up and perform.

Niagara Cutter

Amherst, N.Y.

niagracutter.com

Circle 51

Explore the March 2005 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables