When Marsh Syverson established Engineering Techniques, Inc. in 1978, he quickly discovered the enormous potential that was offered by the then still-young technology of wire EDM. Many conventional processing steps, such as drilling, milling or grinding, could be implemented in one production stage using wire EDM technology.

As Engineering Techniques evolved, the company specialized increasingly in the production of prototypes and small series of parts for the medical, electronics and biomedical industries. The proximity to high-tech businesses in Silican Valley did the rest, supplying demand for high precision prototypes and parts. There was also a call for Engineering Techniques' skills when using wire EDM to turn an idea, sketch done by hand or model into parts ready for use.

Because of its long history in dealing with wire EDM, Engineering Techniques is often a top choice for the economic production of small series of parts. In connection with a medical project for optical surgery, the company received an order to manufacture parts used to position 2mm microchips during eye operations. The material to be machined was 0.0762mm thick foils made of 304 stainless steel.

The part in question had high requirements in terms of contour accuracy and surface quality, so punching was out of the question. The reproducible precision of wire EDM made it the process best-suited for cutting these demanding parts.

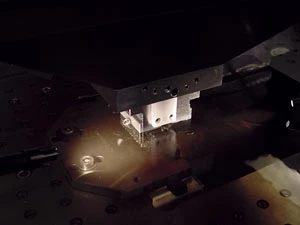

To set up the component for machining, 50 foils were stacked at a time and then pressed between two thicker plates. This not only allowed the parts to be manufactured in a vibration-free environment, but also produced lots of 100 parts from a single setup. For fixing purposes, Engineering Techniques developed a special clamp that was also made via wire EDM. Once the setup was complete, starting holes were drilled, then the fixture was put on an Agiecut Vertex wire EDM for machining.

First of all, the six circles needed on the part were machined with a single cut. Then, the crescent-like contours and lower part of the positioning instruments were cut free. To achieve the required surface quality of Ra 0.1µm, three trim cuts were carried out on the crescent-like section. To ensure the highest contour accuracy without physical influences, the long web of the parts was cut free at the end of the process, with one cut.

In producing this small medical component, Engineering Techniques found its choice of Agie wire EDMs to provide particular value. Reliable threading of even the finest wires in extremely small holes allowed for consistent and productive machining. Efficiency was also increased through the use of two different wire types through the machine's double reels. The Agiecut Vertex also provided high contour accuracy and the repeatability needed for the application. The machine also features a small footprint, allowing it to provide a high amount of value in a relatively small amount of space.

Details on many of the medical components machined at Engineering Techniques are extremely small.

Syverson also credits Agie Charmilles with providing the training, advice and support necessary to fully capitalize on the Agiecut Vertex's capabilities. "A first-class product also needs first-class service," says Syverson. "Agie Charmilles offers us that."

Explore the July 2007 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables