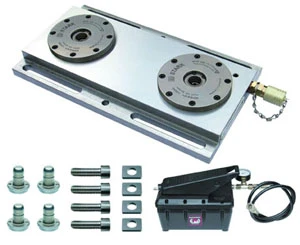

Carr Lane has developed zero point mounting kits which contain all required components to create a quick pallet change system. The heart of the system is the Speedy Module plate which is mounted onto the machine table or tooling block. These module plates clamp onto nipples that are attached to the bottom of existing fixture plates. By attaching nipples to all fixtures, a user can change pallets in a matter of seconds, optimizing short run production. While machining, the operator can set up the next part outside of the machine, maximizing machining time.

The module plates can also be mounted to inspection machines, making it possible to transfer parts from machining to inspection cycles while maintaining the same datum points.

Carr Lane says the new Stark Kits are beneficial for manufacturers struggling with long setups, or manufacturing short-runs of parts.

Carr Lane Manufacturing Co. Saint Louis, MO carrlane.com Booth #E-2124

Explore the July August 2006 Issue

Check out more from this issue and find your next story to read.

Latest from Today's Medical Developments

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor