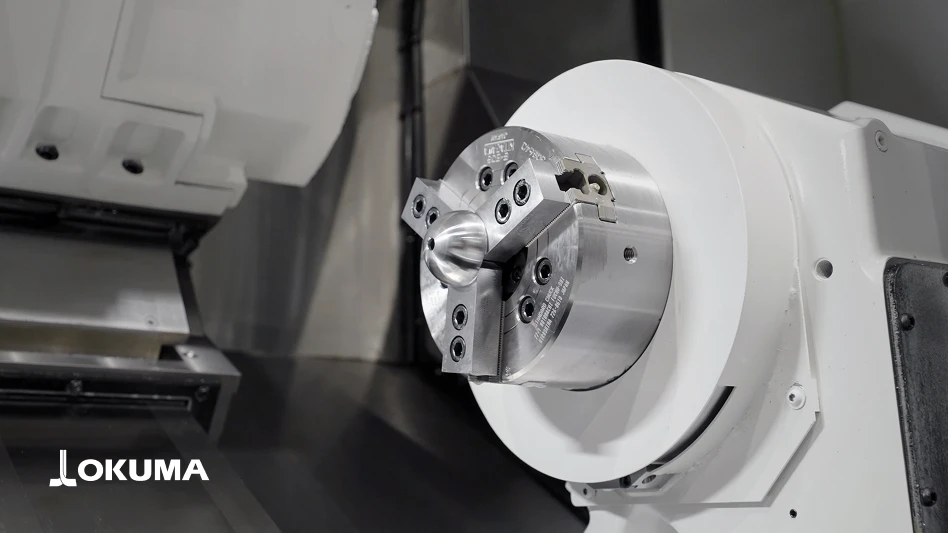

Challenge: Centerless grind two mating metal medical components, with a tight clearance requirement between their surfaces, to create a powered arthroscopic shaver used in orthopedic joint surgeries.

Challenge: Centerless grind two mating metal medical components, with a tight clearance requirement between their surfaces, to create a powered arthroscopic shaver used in orthopedic joint surgeries.

Glebar's centerless grinding solution: Two tubes are assembled, with as minimum a gap between the two parts as possible – sometimes as small as 0.0005" – so that the inner tube moves freely inside the outer tube without allowing debris to get caught between the surfaces. The tips of the tubes typically have a rounded guiding surface, and the outer tube has a window cut in it to expose the sharp edges of the inner tube, both difficult to manufacture in volume.

Using the Glebar GT-610-CNC to infeed centerless grind the shape of the inner tube, we were able to maintain a ±0.0002" tolerance on the tip dimensions. At the same time, we ground three diameter features to within 0.0002” per diameter, maintaining a TIR of 0.0001" and producing a smooth 9Ra surface finish on 304V stainless steel with a ±0.00" wall thickness. We removed 0.012" in stock for the majority of the part and 0.004" off the tip geometry. The entire fully automated process was done in under 20 seconds, adjusting for part length variation, heat expansion, and a near zero tip geometry requirement.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025