CREDIT: LMA CONSULTING

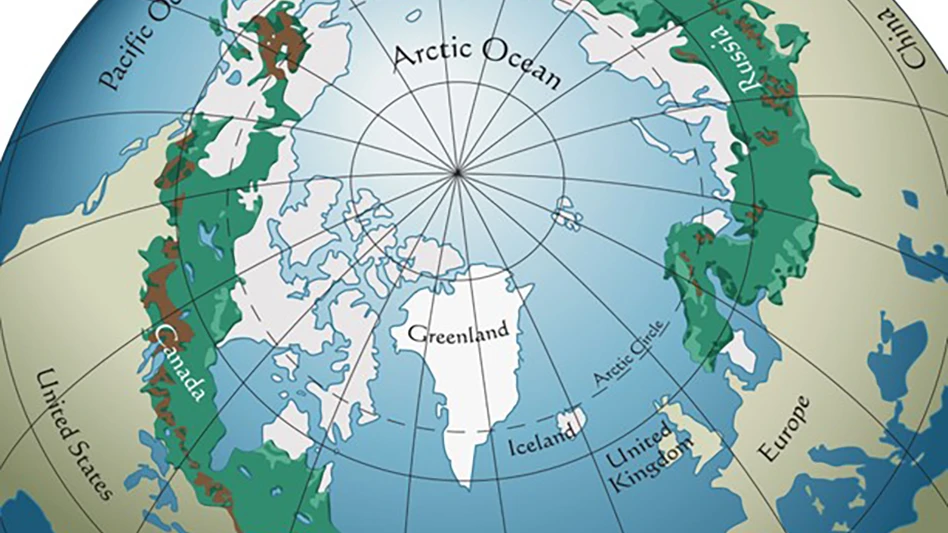

Lisa Anderson, MBA, CSCP, CLTD, a leading expert in manufacturing strategy and supply chain transformation and president of LMA Consulting Group, Inc., is drawing attention to the growing importance of Greenland and its role in safeguarding global supply chains in an increasingly volatile environment.

“Supply chains are only as strong as their most critical links,” says Anderson. “Greenland is emerging as one of those pivotal links – not for political reasons, but because it directly affects how goods move, how industries are protected, and how essential materials are secured.”

Anderson points to three primary factors driving Greenland’s rising importance to manufacturers and supply chain leaders worldwide.

A critical global shipping route

As Arctic routes become more viable, Greenland sits along one of the fastest shipping corridors between Western and Eastern markets. Shorter transit times translate to reduced lead times, lower transportation risk, and improved responsiveness – advantages that are increasingly essential as supply chains must pivot quickly in response to disruption.

Infrastructure protection and supply chain security

Modern supply chains depend on stable infrastructure: transportation networks, energy systems, and communication capabilities. Greenland’s geographic position supports the protection of these systems, which is essential to ensuring continuity of operations and minimizing disruption across global trade networks.

Access to rare earth elements

Virtually every advanced product - from medical devices and electronics to defense-related manufacturing – relies on rare earth elements. Greenland holds significant potential reserves, making it an important consideration for manufacturers seeking to diversify sources, reduce concentration risk and ensure long-term material availability.

“Manufacturers are realizing that resilience is no longer optional,” Anderson explains. “Whether it is securing access to critical materials, shortening supply routes, or protecting infrastructure, these decisions are about keeping supply chains running – not ideology.”

As companies plan for 2026 and beyond, Anderson emphasizes the need to connect these geopolitical realities back to operational execution. “This is where strong data, optimized ERP systems and a disciplined SIOP process become essential,” she says. “You cannot respond to global risk without visibility, coordination, and the ability to make informed decisions quickly.”

These themes are further explored in LMA Consulting’s thought leadership, including its Supply Chain Bytes video series and the firm’s latest eBook, AI & Advanced Technologies in Manufacturing, which brings together insights from experts across industries who work alongside manufacturers and see where supply chain risks and opportunities are emerging.

Latest from Today's Medical Developments

- What’s happening in the defense industry right now

- Hypertherm accepting applications for educational grant program

- Making workholding work for you

- Norman Noble offers medical implant engineering design services

- Lubrizol launches new medical-grade TPU material

- Medical device manufacturers embrace automated quality management

- High-performance hydrophilic coating solution

- Enercon highlights end-to-end electronics capabilities for FDA-regulated medical devices