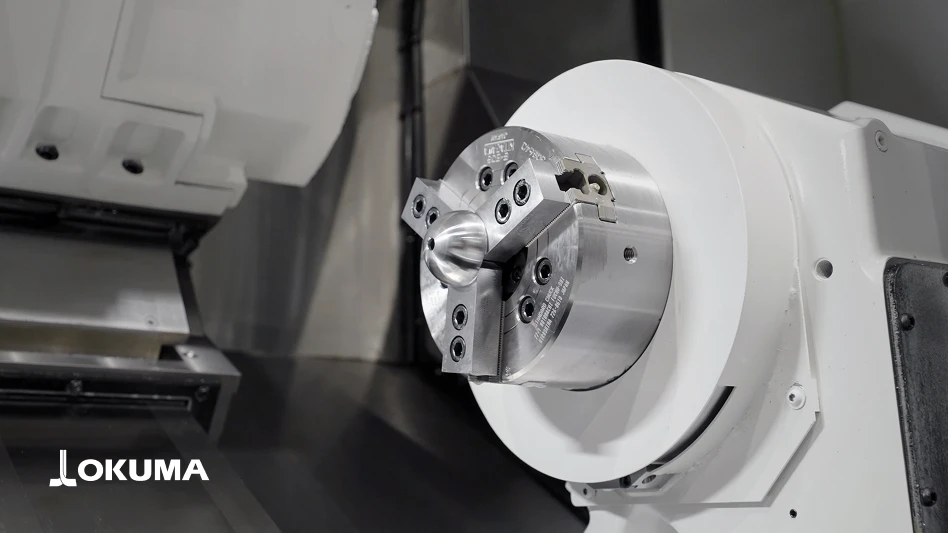

Steven Morris, senior application engineer, and Steve Lenihan, product manager, Lyndex-Nikken, discuss making automation more accessible to manufacturing workers.

In the face of today's shortage of skilled workers, achieving operational excellence and maximizing spindle time has become an even greater challenge for manufacturers. What is needed to address the pressing issue of a skills gap in the workforce is an intuitive pathway to enhance machine efficiency and seamlessly integrate into Industry 5.0, all without requiring an extensive background in robotics or automation. Whether the goal is lights-out machining or harnessing machine data for process improvement, the solution is to simplify the journey and empower machine shops to overcome challenges without the need for advanced expertise.

Backed by over a half century of experience, Lyndex-Nikken`s line of quality toolholders, rotary tables, presetters, machine tool accessories, and automation helps manufacturers improve their accuracy, efficiency, and productivity. Featuring advanced designs and rigid components, their products are built from the ground up for long-lasting precision, reliability, and productivity.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025