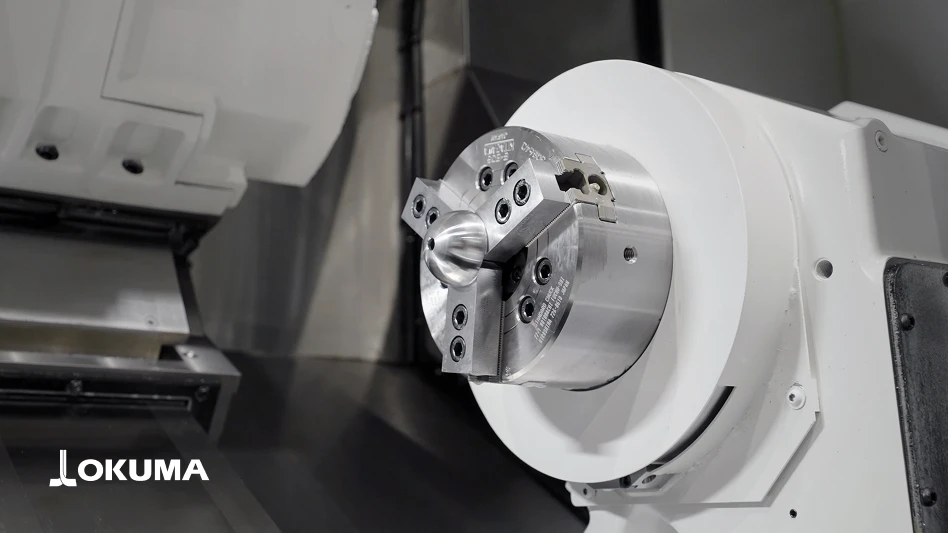

Gisbert Ledvon, vice president of marketing for HEIDENHAIN Corp. in North America, explains how to improve productivity, reduce quality inspection time, and make 5-axis machining more attractive and safe through digital transformation.

The possibilities for digital transformation in 5-axis machining are numerous. They include 6-D graphically guided model aided setup, graphically programming on the CNC, cutting tool inspection and the digital part, improving in-process inspection time, and minimizing energy consumption per part, consequently reducing environmental impact in manufacturing.

HEIDENHAIN develops and manufactures linear and angle encoders, rotary encoders, digital readouts, length gauges and numerical controls for demanding positioning tasks. HEIDENHAIN products are used primarily in high-precision machine tools as well as in plants for the production and processing of electronic components.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025