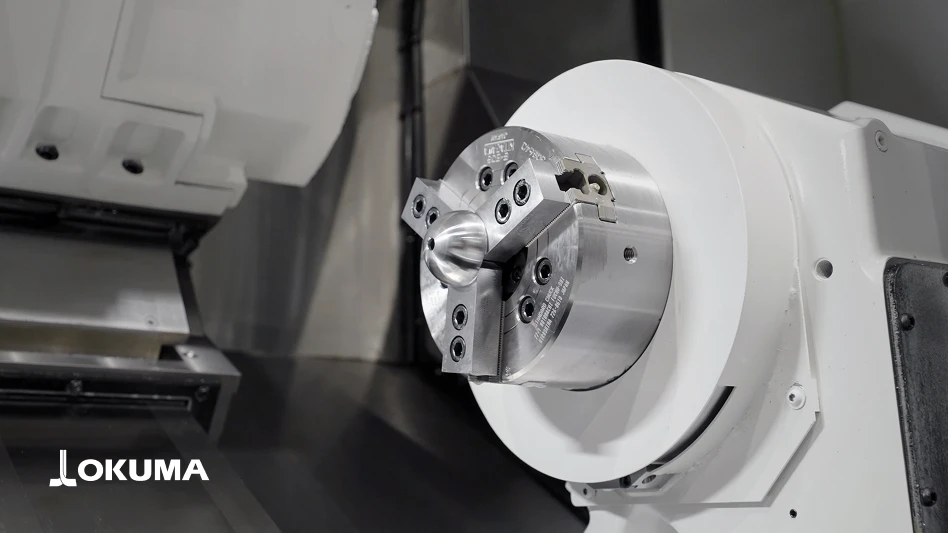

An in-depth approach on developing a 5-axis machining plan, focusing on maximizing machine capacity and achieving the fastest return on investment (ROI) possible.

Jack Rushlander, technical sales manger-East at Jergens Inc., discusses Layout and Planning Techniques for 5-axis Machining Centers.

Walk thru a complete planning process in SolidWorks beginning with raw material and ending with a finished part. Discussions include:

- Machine work envelope considerations

- Raw material and finished part layout

- Machining access considerations

- Maximizing the machine capability

- Planning for automation

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables