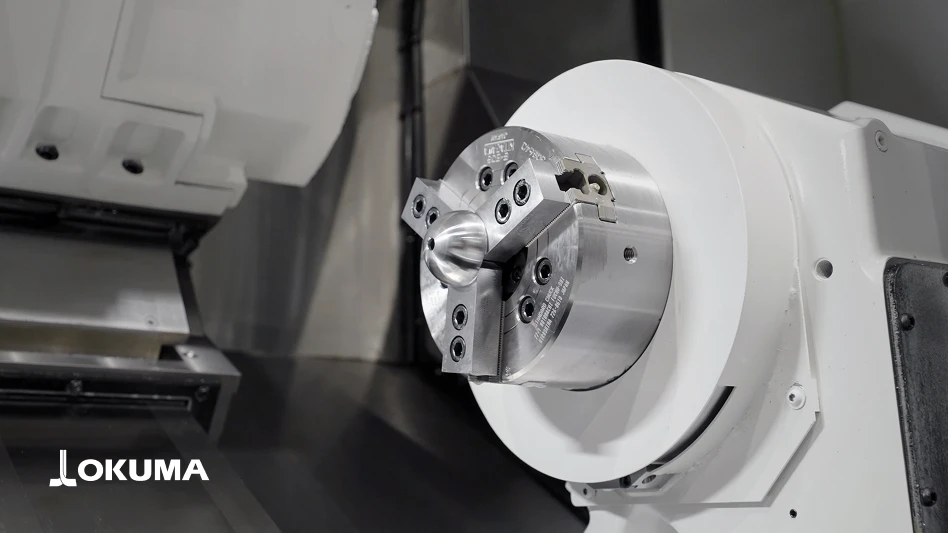

Learn about recent cutting tool innovations related to modular tooling from ISCAR and how these tooling systems can help companies keep spindles rotating while driving down overall costs.

Rigidity is one of the main variables of machining that effects machining productivity and is something that must be accounted for on a consistent basis when making cutting tool decisions. It would be nice and easy if every cutting tool assembly was 1 piece, nice and short (i.e., less bending) with huge tolerance bands in terms of stable machining zones (i.e., no chatter). However, those of you still reading realize this is not our world and understand the many variables to consider when it comes to creating cutting tool assemblies that will be productive for a given application. Robust, modular, tooling systems can make dealing with variables much easier. This lunch and learn will highlight recent cutting tool innovations related to modular tooling from ISCAR and how these tooling systems can help companies keep spindles rotating while driving down overall costs.

Gain more insights when you view the presentation.

Latest from Today's Medical Developments

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor