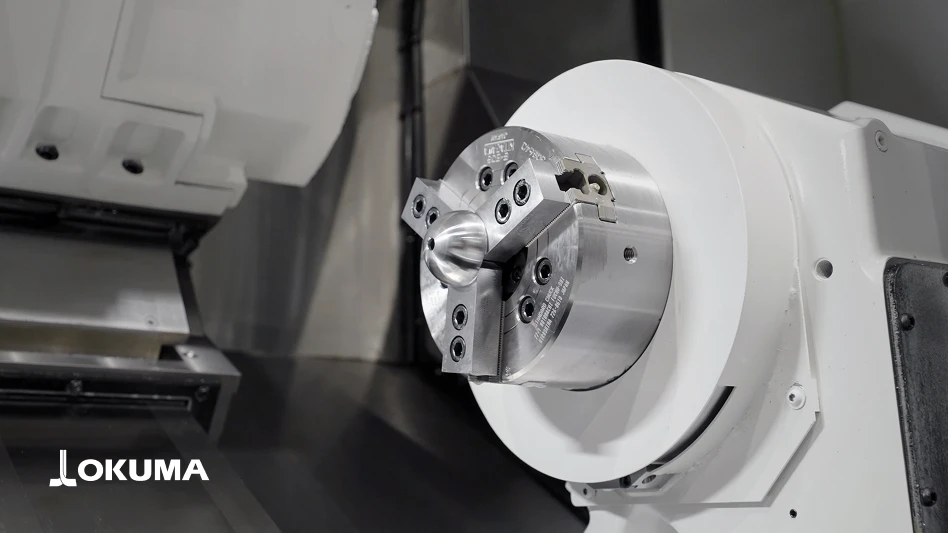

Learn a new approach and see how programming ultrasonic knife cutting with hyperMILL is easily accomplished and provides NC code simulation to reliably bring challenging 6-axis output to the machine.

Kevin Lewis, an Account Manager for OPEN MIND Technologies, USA covering the western region, explains how ultrasonic knife cutting represents an ideal solution for the efficient cutting of advanced materials including honeycomb, composites, and foams. Creating the required 6-axis NC programs (five machine axes plus a programmable spindle orientation) has historically proven a challenge.

Learn a new approach and see how programming ultrasonic knife cutting with hyperMILL is easily accomplished and provides NC code simulation to reliably bring challenging 6-axis output to the machine. hyperMILL’s Optimizer controls the orientation of the spindle, as the sixth axis, to align the cutting blade to the workpiece while guaranteeing optimal machining within limits for demanding machines with limited rotation axes, such as fork heads.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025