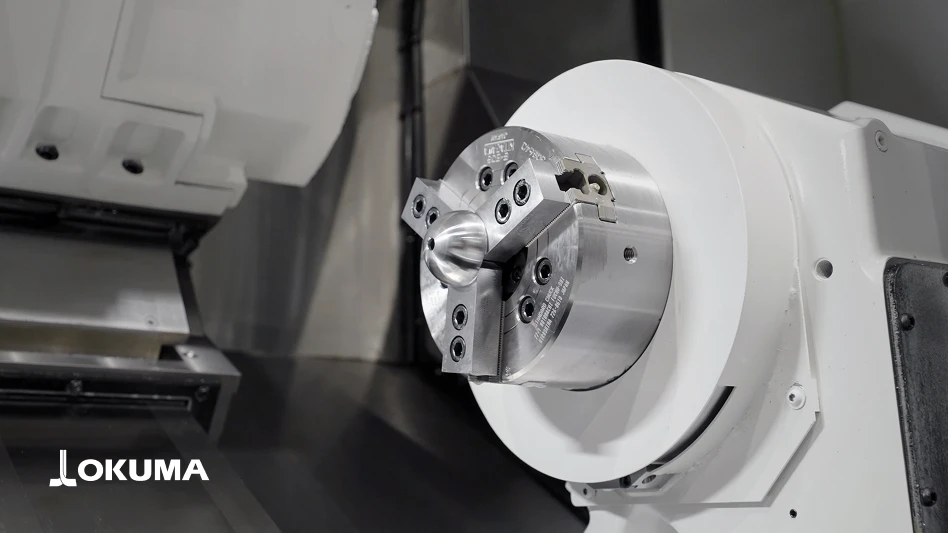

Learn how ground-breaking innovations in the CNC machining workflow can have a huge impact on several pain points in the industry.

Rachel Short, managing director at Norgren Inc. discusses Creating Adaptable Solutions to Improve Workholding Technology Efficiency.

The COVID-19 pandemic and the pressure it has placed on supply chains, hiring needs, and skills training has only exacerbated the inherent inefficiencies of existing approaches to workholding.

Current workholding processes involve single-application aluminum soft jaws, which introduce resource challenges and require a significant amount of time, skill, and raw material, even before a single part is milled. Re-thinking traditional soft jaw processes to focus on adaptable solutions can eliminate entire steps from an existing process, simplifying workflow and curtailing the time, effort and cost expended in traditional workholding.

Learn how ground-breaking innovations in the CNC machining workflow can have a huge impact on several pain points in the industry. Furthermore, you will see how allowing lean in-house manufacturing operations and limiting vulnerability to supply chain disruptions will ultimately save your operation time

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025