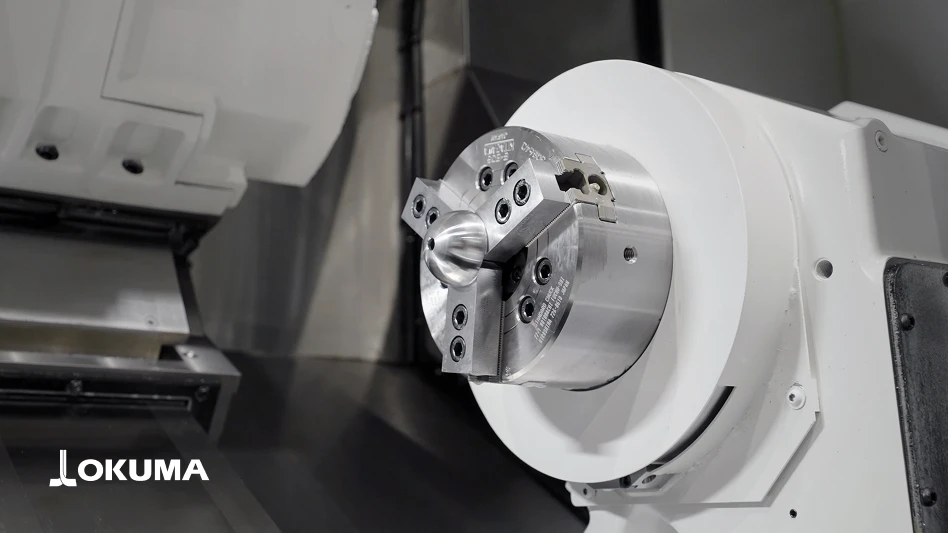

SW worked with the customer to develop an efficient, space- and labor-saving solution centered around an automated BA 321 machining center, which mills the forceps halves.

SW’s twin-spindle BA 321 machining center produces two forceps halves every 3 minutes, making it an extremely efficient solution. The use of oil as an emulsion ensures optimal precision and surface quality, resulting in dimensionally accurate workpieces with impeccably smooth surfaces. As with all of SW’s machining centers, the BA 321 is perfectly suited for automation solutions.

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables