Guill Tool & Engineering

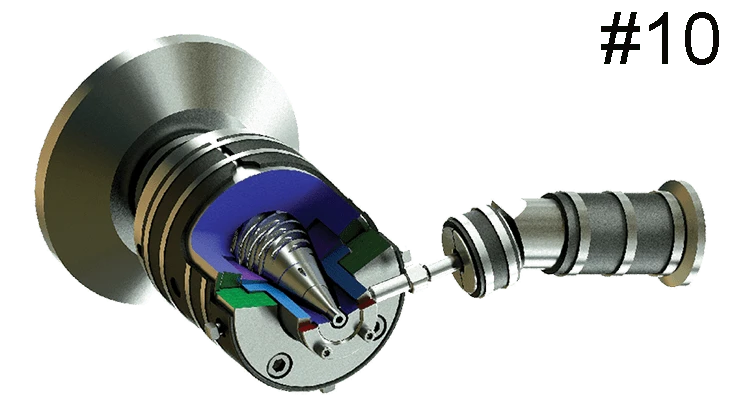

State-of-the-art production equipment and processes hold extremely close machining tolerances when producing multi-lumen and multi-layer medical tubing. However, tool misalignment or maintenance issues can produce exaggerated impacts on the final product.

Equipment maintenance

Improperly maintained equipment can waste 10% to 20% of the material, which can run from 50% to 90% of product cost, since in extrusion processes materials costs are typically higher than labor costs. Tooling suppliers go to great lengths to maintain tips and dies to a determined specification, ensuring perfect concentricity and alignment. Proper maintenance keeps it that way.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025