Unisig

For deep holes in components to be accurate – such as surgical tooling – they need to uphold tight concentricity tolerances. In gundrilling, this is best achieved with counter-rotation. For a manufacturer, this is vital. For a surgeon and patient, it can make all the difference.

Manufacturers achieve concentricity tolerances when the hole follows the desired axis of the part, eliminating drift from the point of entry to the exit. In a round part with on-center drilling, this is easily illustrated; some applications may include off-center deep holes or holes in non-round parts that still have tight concentricity requirements.

Low concentricity in some applications can weaken sidewalls, lead to mismatched holes, or force producers to scrap parts. Adding a counter-rotating process on deep-hole drilling equipment allows manufacturers to economically achieve critical tolerances.

With the right equipment and setup, counter-rotation is possible for smaller gun-drilled holes or larger, longer, Boring Trepanning Association-drilled (BTA) components.

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

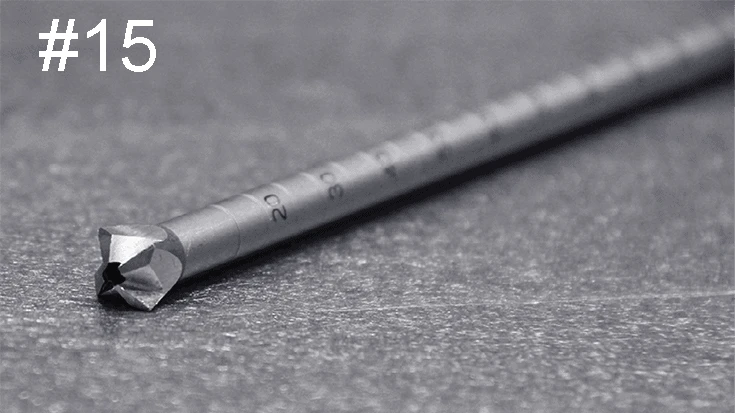

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables