Unisig

For deep holes in components to be accurate – such as surgical tooling – they need to uphold tight concentricity tolerances. In gundrilling, this is best achieved with counter-rotation. For a manufacturer, this is vital. For a surgeon and patient, it can make all the difference.

Manufacturers achieve concentricity tolerances when the hole follows the desired axis of the part, eliminating drift from the point of entry to the exit. In a round part with on-center drilling, this is easily illustrated; some applications may include off-center deep holes or holes in non-round parts that still have tight concentricity requirements.

Low concentricity in some applications can weaken sidewalls, lead to mismatched holes, or force producers to scrap parts. Adding a counter-rotating process on deep-hole drilling equipment allows manufacturers to economically achieve critical tolerances.

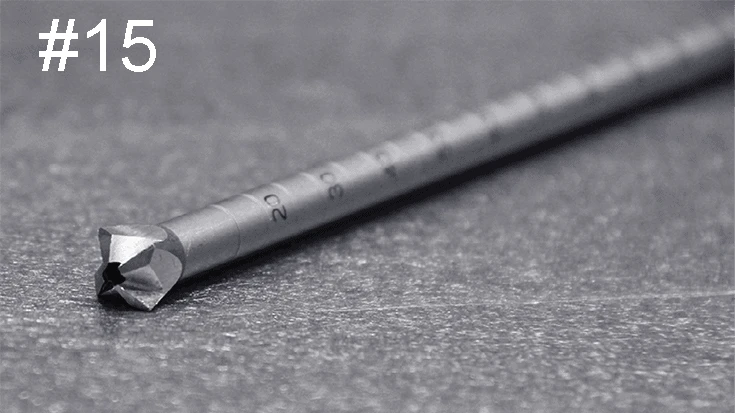

With the right equipment and setup, counter-rotation is possible for smaller gun-drilled holes or larger, longer, Boring Trepanning Association-drilled (BTA) components.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.Latest from Today's Medical Developments

- AI will power the next generation of medical wearables

- CUI Crash Course from Smithers

- Revolutionary implant harnesses electricity for healing

- Discover the advantages of Oerlikon's latest Surface Two technology

- #48 Lunch + Learn Podcast with OPEN MIND Technologies

- CERATIZIT achieves SBTi validation for emissions goals

- Applied Motion Products’ MLA & MEA series linear actuators

- Arterex expands portfolio with Xponent Global acquisition