Costa Mesa, California – Adaptive Designs is a provider of 3D printing, 3D scanning, production 3D printing, rapid prototyping, and additive manufacturing services. Parts produced are high resolution and tough enough for use as working parts, allowing customers to test fit the prototypes and the production parts in a cost effective way.

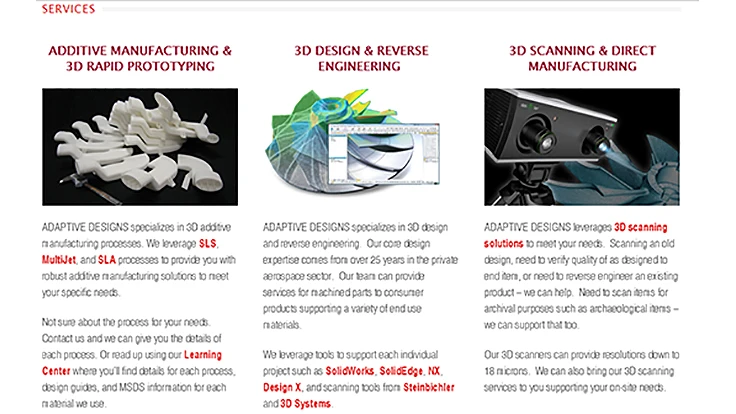

Adaptive Designs features the latest technology in 3D scanning to render an object as a 3D model. Siemens NX, SolidWorks, SolidEdge, and Design X are used as tools to help customers get projects completed quickly and efficiently. Any project can be adapted to a customer’s needs. A wide range of processes and tools for rapid prototyping are used – direct digital manufacturing, 3D printing, 3D scanning, and traditional processes such as machine services.

Using Stienbichler & 3D Systems blue light scanners, Adaptive Designs’ engineers deliver above standard results for reverse engineering, product validation, product verification, and quality assurance. This type of scanning is used for design, archaeology, medical purposes, reverse engineering, rapid prototyping, manufacturing, quality control, inspection, mold, and tool making.

3D printing services include: selective laser sintering (SLS), stereo lithography (SLA), and multijet (MJP). Each part printed must meet process specifications or the customer’s requirements. Adaptive Designs also supports processes other than those listed.

MJP is a printing process that Adaptive Designs uses to build parts with a fine feature detail. This type of inkjet 3D printing process uses piezo print head technology. Piezo technology is based on a phenomenon of piezoelectricity where materials such as ceramics, biological matter, and crystals react physically by vibrating, expanding, or bending when an electrical charge is applied. The piezo print head deposits plastic resin or casting wax layer by layer to build parts, patterns, and molds. The resin or wax can be printed in to electronic housings, automotive prototypes, hydroform tooling, jewelry, aerospace prototypes, consumer goods, injection mold tooling, medical, and dental applications.

Source: Adaptive Designs

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025