When integrating a rechargeable battery into a professional application, especially into a mission critical medical or military device, the first things that come to mind are reliability and safety. However, there are many other factors designers need to consider throughout the various stages of custom battery design.

Michele Windsor, direct sales and marketing manager at Accutronics, guides design engineers through the process of embedding batteries in medical, military, or automation applications.

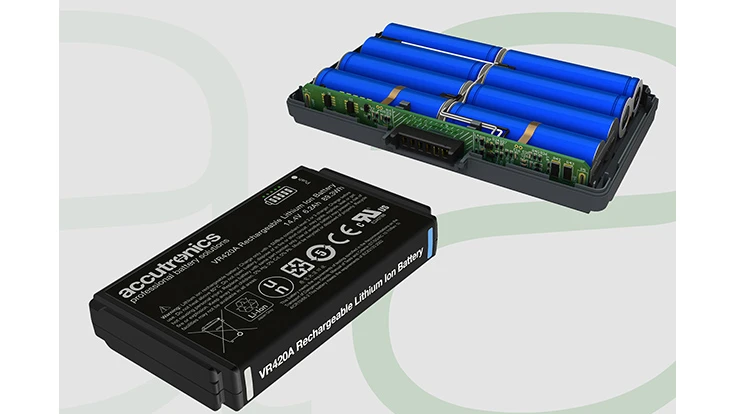

Many design engineers believe that, as its power source, the battery is the very heart of the product. However, Windsor goes even deeper into the core of the battery, arguing that it’s the cell that is the nucleus of the battery, determining the performance, lifecycle, and durability of the application.

There is no such thing as a typical battery design project. This is partly because custom power sources are used everywhere from hospitals to manufacturing plants and military operations. Some customers might be looking for high-energy capacity, while others might need low-temperature performance, high-availability, a longer cycle life, or a specific battery size. In other words, finding out exactly what you want the battery to do for your piece of equipment is crucial to the success of the design.

1. One fundamental guideline is to decide whether the battery must withstand extreme conditions such as freezing temperatures, scorching heats, humidity, or dirt. To guarantee efficiency, we select only the type of cells that are suitable to these conditions. In these instances, the electronics need to be programmed differently to cope with the various environments, while the physical characteristics of the battery need to be robust enough for the given extremes.

Intelligent cell selection can also help ensure the future availability of the battery, which means the cell can be replaced if a superior version becomes available. This guarantees a longer life cycle for your battery and helps alleviate obsolescence related issues.

2. The physical characteristics of a battery, such as its size, durability, and weight, also play a crucial part in its design. Similarly, performance characteristics such as efficiency, reliability, and availability are also essential. For instance, portable medical devices might require a high tolerance to vibration, so that they can be used while transporting patients by helicopter. Achieving this is a matter of managing the physical and performance characteristics simultaneously, which is no mean feat.

3. Another important factor to consider, and one that applies to the integration of all sub-assembled components, is the availability of parts and their potential obsolescence. For this reason, engineers should avoid designing-in off the shelf consumer batteries. Windsor’s experience has shown that these are poorly supported technically and very likely to become obsolete quickly. Simply choosing a customised industrial or professional battery, designed with your application in mind, guarantees you a lifetime of support.

4. Once a battery prototype has been developed, the final stage is to certify that product for use, from both safety and performance perspectives. Accutronics normally manages the entire approval process on behalf of its customers. Each battery design undergoes the appropriate safety testing from, for example, the IEC (International Electrotechnical Commission), the UL (Underwriters Laboratories), as well as the IATA (International Air Transportation Authority), and military standards testing from MIL (The US Department of Defence Test Method Standard for Environmental Engineering Considerations and Laboratory Tests), if relevant.

It is clear why the battery is the very heart of many medical, military, and industrial electronic devices. Windsor also argues that it is the quality of the design process that ensures the heart will continue to beat during the lifespan of the OEM's device.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025