Los Angeles, California – The University of Southern California has established a new center focused on Advanced Manufacturing with the focus to support a comprehensive program in advanced manufacturing.

Goals of the center are:

- Grow manufacturing research at USC by launching new initiatives;

- Enrich educational experience of students and help in attracting high quality students to USC

- Provide access to the latest manufacturing technology to the USC community

- Support manufacturing industry in the Southern California region

The vision of the center is to improve lives through advances in manufacturing by:

- Broadening the pool of inventors

- Enabling innovation to grow manufacturing industry

- Realizing flexible manufacturing at affordable costs

- Creating jobs by enabling in-shoring

- Reducing environmental impacts of manufacturing

Its mission is to support the Viterbi School and its partners by:

- Conducting basic and applied research to enable advances in manufacturing

- Identifying new opportunities in manufacturing areas and launching new initiatives to address them

- Developing interdisciplinary manufacturing education programs

- Supporting outreach to the K-12 community

- Providing access to advanced manufacturing capabilities to the USC community

- Providing manufacturing expertise to companies in the Southern California region

- Transitioning research results into industrial practice

Four focus areas of the center are:

Focus Area 1 – Digital Manufacturing – This area leverages the latest advances in the information technology and computing areas to realize tools and methods to reduce reliance on physical prototyping, to enable distributed collaboration in global environment, and to manage information. Representative areas include:

- Virtual prototyping of complex products

- High fidelity simulations of manufacturing operations

- Manufacturing system design and optimization

- Automated planning, instruction generation, and cost estimation

- Product life cycle management (PLM)

Focus Area 2: Additive Manufacturing – This area focuses on making advances in the additive manufacturing processes to enable the realization of innovative products. Representative topics include:

- Multi-material processes

- Multi-scale processes

- Processes for creating multi-functional structures

- Automated post-processing

- Metrology

- Process modeling and control

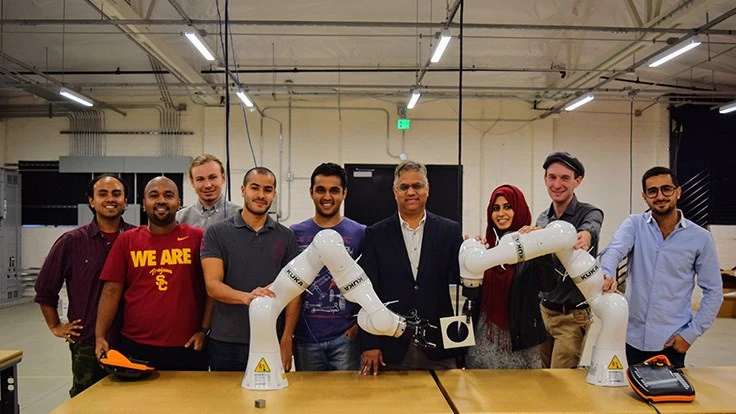

Focus Area 3: Robotics and Automation – This area focuses on the development of technologies to reduce human labor and manufacturing and hence make manufacturing cost-competitive in the US.

Representative topics include:

- Mobile manipulation

- Low cost custom robots

- Assemblies with highly compliant parts

- Automation for meso-, micro-, and nano-scale assemblies

- Learning from demonstrations

- Human robot collaboration

Focus Area 4: Smart Manufacturing – This area focuses on improving resource use, reducing errors, and increasing responsiveness to changes. Representative topics include:

- Exploit Internet-of-Things

- Efficient resource use

- Energy efficient manufacturing

- Energy efficient automation

- Multi-modal sensing for process monitoring

- Big data for prediction and optimization

- Contingency planning to recover from errors fill-reg

Source: USC

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables