Lake Region Medical GmbH needed a cleaning process that causes no damage to the product while meeting stringent specifications on the removal of particulate, film-type, and microbiological contaminants.

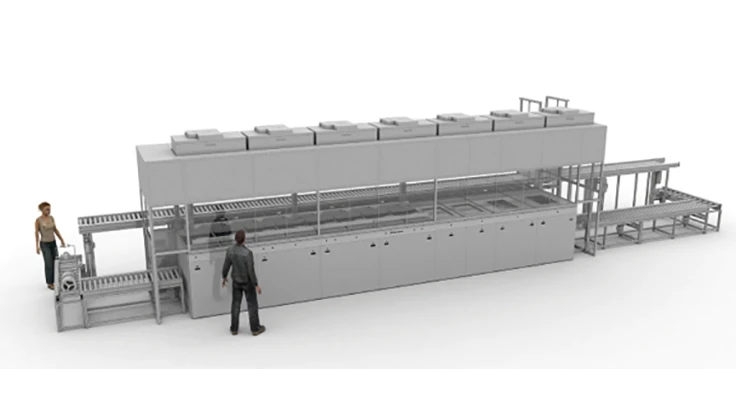

Ultrasonic Cleaning Machines (UCM AG) of Switzerland responded with an ultrasonic fine-cleaning system that provides reliable cleaning of more than 1 million stainless steel turned parts and tubes per day, six days a week – with products being discharged directly into a good manufacturing process (GMP) Class D cleanroom.

In 2013, a Lake Region Medical customer from the pharmaceutical/med-tech sector needed to expand cleaning capacity for stainless-steel turned parts and tubes. The company decided to outsource this operation to Lake Region Medical. Under the contract, the equipment required for this process had to achieve given levels of cleanliness – with limits on particulate, film-type, and antimicrobial contaminants – while also ensuring that the parts would emerge from the cleaning process undamaged. An additional challenge resided in the product geometry. The turned parts – measuring up to 10.0mm in diameter – have very fine drilled holes. The tube parts are up to 60.0mm long, with internal diameters of only 0.4mm, and must be consistently and reliably cleaned inside.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025