Cleveland, Ohio – FANUC Corp. and MachiningCloud announce their partnership to provide integrated management of tool information at the shop floor. MachiningCloud is a product data provider for cutting tools, CNC machines and workholding. FANUC Corp. is the developer of iHMI, Intelligent Human Machine Interface. FANUC iHMI is a user interface for consistent support of shop floor operation by providing the necessary functions for each process - "planning", "machining" and "improvement".

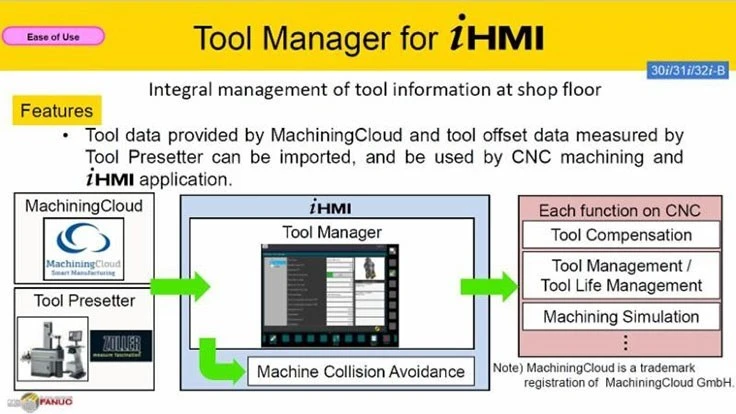

FANUC iHMI is not only function for display but also a kernel platform of making the machine IoT, which has functions of uploading machine and sharing information to upper system. The MachiningCloud, iHMI solution was on display in FANUC Corp.'s booth during JIMTOF 2016 at Tokyo Big Site, Japan. This partnership will integrate management of tooling resources within one platform. Tool data provided by MachiningCloud and tool offset information measured by tool presetters, such as Zoller, also a MachiningCloud partner, can be imported and used by CNC machining and iHMI.

With MachiningCloud, FANUC's customers will have a simpler way to find the right cutting tools as they will have direct access to current and complete tooling data without the hassle of searching through printed catalogs and multiple websites to find ideal tooling. This convenience and accuracy will save time and increase efficiency on the shop floor.

“We are excited about our collaboration with FANUC Corp. as the combination of FANUC's new iHMI along with the capabilities of Zoller's tool measurement capabilities on MachiningCloud, the CNC world will gain new operational efficiencies – one step closer to the promise of Industry 4.0 and Smart Manufacturing initiatives,” says Chuck Mathews, managing director and cloud evangelist for MachiningCloud.

About FANUC Corp.

FANUC has consistently pursued the automation of factories since 1956, when it succeeded in the development of the servo mechanism for the first time in the Japanese private sector. FANUC contributes to the promotion of automation for customers, with the three pillars consisting of the FA Business Division, based on its basic technologies of NC and servo, and the Robot Business Division and Robomachine Business Division, which apply these basic technologies.

About MachiningCloud

MachiningCloud is dedicated to leading a digital shift within the discrete manufacturing industry to deliver a new level of operational efficiency. Cloud-based applications, resources, services, knowledge, and digital product data from the world's leading manufacturers of cutting tools, machine tools, workholding and specialty products are providing efficiency improvements by facilitating the flow of data to and from today's data intensive shop-floor.

For cutting tool manufacturer's and their customers, the MachiningCloud app is an Industry 4.0 solution delivering up-to-date cutting tool manufacturers' product knowledge and data, fast-tracking cutting tool selection, CNC programming, simulation and shop floor operations. By providing data from the world's leading suppliers, MachiningCloud eliminates the hassles of searching through printed catalogs, telephone calls and multiple websites to find optimal tooling, while also removing the burden of manually typing tooling data into CAD/CAM software.

Source: MachiningCloud

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025