CREDIT: ADOBESTOCK_122562046

When evaluating the numerous injection molding companies in the United States, it’s important to have clear criteria to identify the partner best suited to your project. Selecting the right supplier requires assessing engineering support, production capacity, and supply chain stability. The following factors will help you make a well-informed decision and minimize risks throughout your manufacturing process.

- Quality certifications: ISO 9001 certification is the basic requirement. For specialized industries like aerospace or medical devices, certifications such as AS9100 or ISO 13485 are more relevant. You can verify certification validity through third-party certification bodies and assess compliance based on supplier-provided case studies or qualification documents.

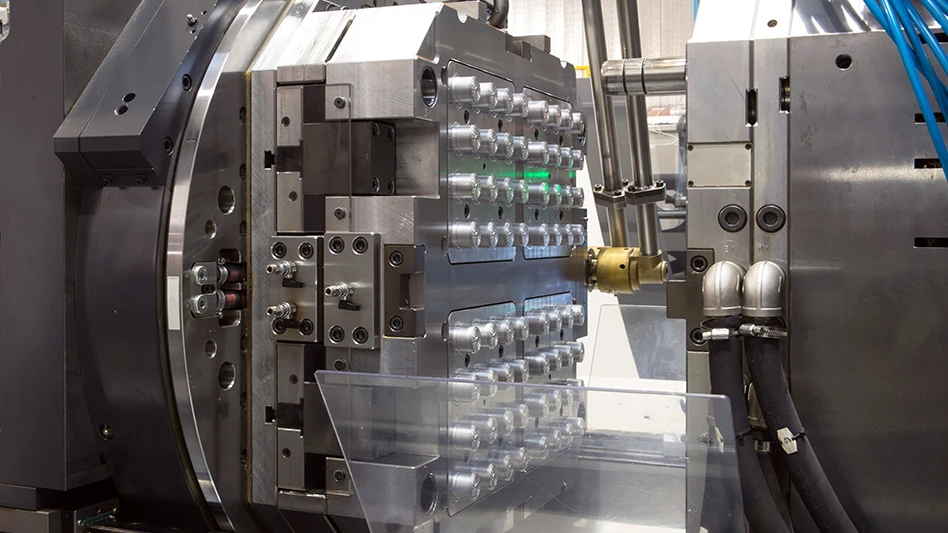

- Tooling capabilities: Focus on mold design experience and tooling material quality. Molds made from P20 or H13 tool steel with proper heat treatment typically achieve lifespans exceeding 500,000 cycles. Confirm their design validation procedures and maintenance programs to ensure consistent production quality.

- Engineering support: Reliable suppliers usually engage in Design for Manufacturing (DfM) analysis during the quoting phase. Check whether they have in-house tool design teams and materials experts who can help optimize designs and minimize costly revisions.

- Production flexibility: Assess the supplier’s ability to scale from prototypes to full production volumes. Facilities equipped with multiple presses of varying tonnage are better positioned to handle diverse project requirements and avoid capacity constraints.

- Supply chain reliability: Prioritize suppliers sourcing materials locally and maintaining backup production sites to reduce supply chain risks. Evaluate delivery performance through historical records, third-party reviews, or industry reputation to gauge operational consistency.

Wrapping up

Small- to medium-sized injection molding companies in the USA are leading the way for a rapidly growing industry. Injection molding is one of the world’s most common and widely used manufacturing processes. These companies have made great strides in quality, efficiency, and sustainability. They are continuing to play an essential role in driving innovation and progress within the sector.

They provide a wide range of services and products to meet customers’ needs quickly and accurately. With their commitment to ongoing research and development, these companies will continue to be at the forefront of this ever-evolving industry.

You can choose any one of these companies in the USA that suits your next injection molding project. Best of luck!

Before you get started, here are some common questions buyers often ask when working with U.S. injection molding suppliers.

FAQs About Working with U.S. small to medium sized injection molding companies

Q: What should I prepare before reaching out to a supplier?

A: It’s helpful to provide a 2D drawing or 3D CAD file of your part, expected order quantity, material requirements, and any special tolerances or certifications needed. This helps the supplier give you a faster and more accurate quote.

Q: Can I get samples before mass production?

A: Yes. Most suppliers will provide T1 samples or small trial batches after mold completion. This allows you to inspect part quality and request design adjustments before committing to large-scale production.

Q: Do U.S. suppliers assist with product design or DfM feedback?

A: Many U.S.-based molding companies offer DfM support to help optimize your part for cost, moldability, and function. Early engineering input can reduce rework and speed up production.

Q: Can I visit the factory or audit it remotely?

A: Yes. In-person visits are usually welcomed by appointment, and many suppliers now also offer virtual audits through video calls or facility walkthroughs to support remote customers.

Q: Will my design files be kept confidential?

A: Reputable suppliers adhere to strict confidentiality practices. If you’re concerned, you can request a non-disclosure agreement (NDA) before sharing technical files.

Q: How USA moldmakers & molders beats offshore pricing?

Latest from Today's Medical Developments

- Syringe-less injector system for diagnostic imaging obtains fourth FDA clearance

- Hohenstein Medical debuts enhanced medical device testing capabilities

- Arterex unveils unified brand identity

- Dymax demonstrates light-curing material solutions for medical devices

- Able Medical Devices showcases latest sternal closure solutions

- TMTS 2026 explores AI-powered sustainable manufacturing and more

- QT9 QMS platform streamlines quality management, compliance for medical device manufacturers

- Spineology releases patient-specific expandable spinal implant