CREDIT: LUBRIZOL

If you’re engaged in endoscope design, you know scopes now fulfill functions that extend beyond simple visualization. They’re increasingly utilized for facilitating biopsy and polyp extraction, managing hemorrhage, dilating strictures, positioning stents, and executing suction and irrigation, as well as administering medications. Essentially, the scope is transforming from a camera into a true procedural platform.

The evolution of this device means that, now more than ever, medical professionals must weigh the trade-offs between reusable and single-use alternatives, while recognizing that modern scopes are elaborate medical systems made up of various materials, with each layer becoming increasingly more important.

The single-use market surge

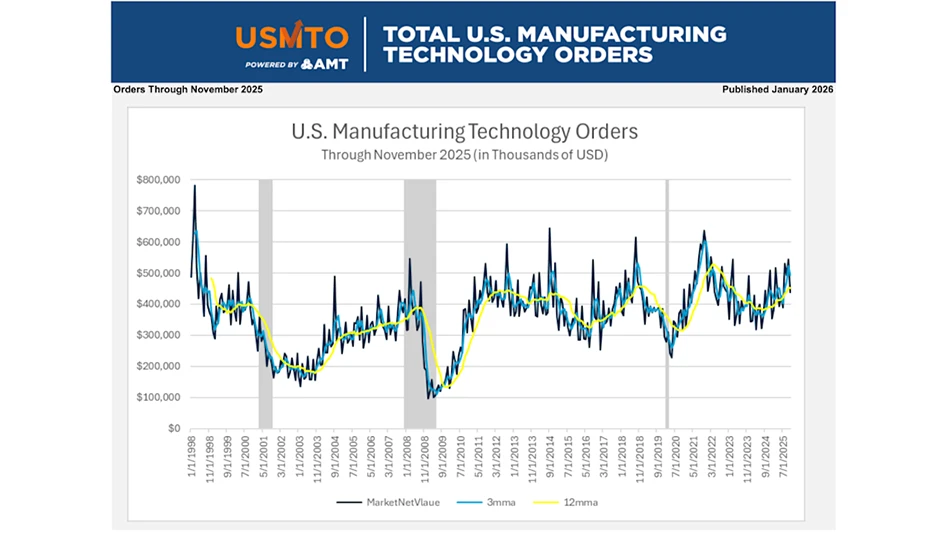

The global endoscopes market (about $25 billion today) is expected to surpass $33 billion by 2030. Reusable endoscopes still account for 87% of total share; however, single-use systems are poised for significant growth during this time, from $2.6 billion currently to over $5.6 billion.

This growth is driven by many factors including infection-control committees striving to reduce cross-contamination risks, perioperative leaders pursuing faster room turnover, and administrators who value per-procedure cost reliability. Single-use scopes are also seeing significant growth where efficiency and hygienic processes are crucial, such as gastrointestinal (GI) and urology procedures, bedside bronchoscopy, and certain clinic-based ENT.

Reusable scopes will continue to be favored in situations where the risk of infection is minimal and where procedures are lengthy and intricate. Single-use scopes remain cost-prohibitive in these situations, largely due to the high cost of the optical components needed to deliver the same image quality as reusable models.

The realistic outcome is an increasingly mixed fleet. For devices intended for reuse, development teams will continue to select material combinations according to the duty cycle, prioritizing chemically resistant jackets, strong bonds and coatings, as well as properties that maintain stability during reprocessing cycles. For single-use devices, the emphasis is on delivering required performance and features with simpler, cost-effective constructions.

More broadly, the industry is moving toward single-use and working to define where they make sense, given their possible higher per-use cost and potential environmental load. An effective materials portfolio should meet clinical performance in both single-use and reusable paths while giving supply chains and finance clear, defensible trade-offs to scale responsibly.

Where TPU fits

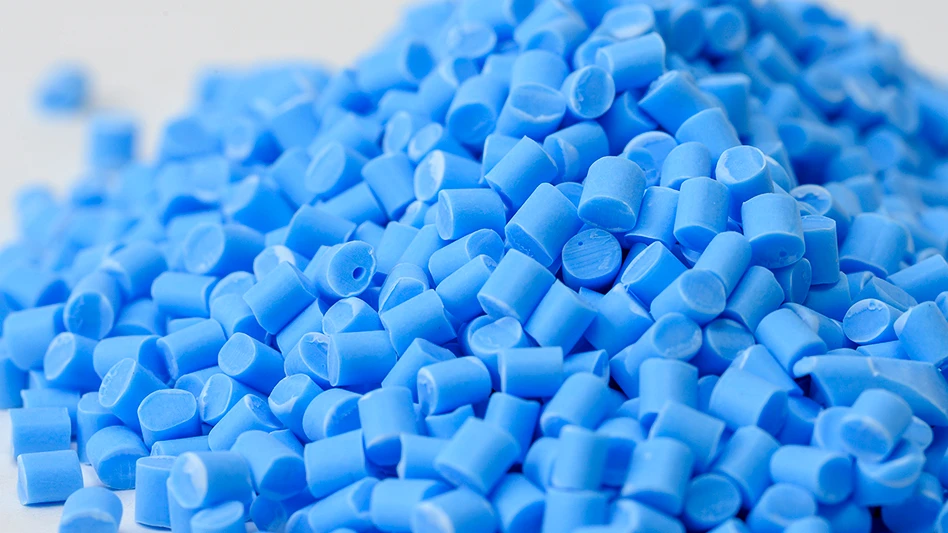

Thermoplastic polyurethane (TPU) has been a cornerstone of medical device innovation since the Pellethane brand was launched in the 1960s, and there are many predicate scopes that include TPU content. The attractiveness of the material lies in its chemistry: a hard-soft segment structure tunable for thin-wall extrusion, kink resistance, strength, and chemical resistance across a broad durometer range. Softer TPU formulations are ideally suited for insertion tubes, selected distal components and housings/over-molds. Meanwhile, rigid TPU can provide more sterilization tolerance and lower risk of stress-cracking compared to polycarbonate for use in the control section.

Developers are also focusing on TPUs that can withstand sterilization while exhibiting a consistent, predictable modulus drop when used in the body. Additionally, in light of PFAS concerns, these materials can reduce the need for fluoropolymer outer layers while maintaining durability and bond integrity.

Certainly, the contemporary design of endoscopes represents a collaborative platform that continues to incorporate a variety of materials:

- PTFE/FEP persists for ultra-low friction properties, rendering it suitable for liners in operational channels and in any situation where stick-slip adversely affects performance. Historically, PTFE has been utilized externally as a chemical-resistant coating for reusable items; yet factors such as availability, cost, and policy exposure are encouraging teams to evaluate long-term alternatives at an early stage.

- Pebax continues to be a reliable material within the catheter class. Although TPU generally provides superior strength and chemical resistance in various constructions, Pebax can deliver enhanced torque response in specific shaft designs.

- Silicone retains a home in catheter balloons and over-tubes especially, thanks to conformability and feel.

- PVC continues to be utilized in subcomponents that have reduced physical property requirements, with emphasis on cost (be aware of the implications regarding plasticizers and regulatory factors).

How TPU helps hit the targets

With the stack in mind, the question becomes, “Why TPU now?” Throughout all duty cycles, TPU frequently serves as the integrator by facilitating durometer gradients, seamlessly integrating into multilayer constructions, allowing for radiopacity and color management, and by adhering effectively to standard liners and jackets.

For all types of endoscopes, teams are focusing their designs on larger inner diameters (ID) while maintaining the same outer diameter (OD). This allows larger or dual-purpose tools without necessitating alterations to the access route. It also minimizes the push force and stick-slip during exchanges, enhances suction capabilities, and decreases the likelihood of clogs that could impede a case.

It’s also more patient friendly: doing more through the same access path can reduce procedure counts, avoid upsizing or new incisions, and shift cases to outpatient settings (often without adding new platforms or extra devices). The compromise involves engineering thin walls that can still maintain column strength, torque, and kink radius at body temperature, paired with ultra-low-friction liners that enable rapid tool movement without causing peel or particulate generation.

From requirements to materials, the advantages show up in these areas:

- Strength. Single-use shafts still need column strength to keep the lumen open under suction and aggressive articulation; TPU supports precise, defect-free extrusion yielding thin, uniform walls that maintain column strength. Rigid TPU housings and over-molds can exhibit superior resistance to stress-cracking during sterilization, transportation, and initial deployment, compared to many rigid plastics of similar thickness.

- Flexibility. TPU’s tunable hard-soft chemistry stays predictable in the body, which allows durometer gradients (stiffer proximal, softer distal) without changing the base resin chemistry. It also bonds well to braid/coil, letting engineers lock in torque transmission with thin jackets thanks to good flex-fatigue, low set, and manageable hysteresis.

- Chemical resistance. Most TPU tolerates common sterilization methods like EtO. Its strength and durability also allow for reduced part failure on multiple sterilization cycles, which can be a big benefit and reduces the cost of reprocessing reusable scopes.

- Kink resistance. The exceptional strength-to-flex ratio of TPU prevents kinking in tight radii, ensuring the lumen remains unobstructed during procedures.

- Torqueability. Transmission of torque is a system property. Braid/coil picks‑per‑inch and the jacket’s modulus do the heavy lifting. TPU jackets over reinforced cores help preserve torque while allowing thin walls.

- In‑body softening. TPU’s predictable modulus drop and recovery let teams tune the feel across the shaft. Where soft touch at the distal end is essential, TPU over‑molds and silicone tips cushion tissue contact while maintaining shape recovery.

Having established these performance targets, the subsequent step involves converting the criteria into components: the liner responsible for establishing friction and peel strength, the reinforcement that supports torque and column strength, the outer jacket to withstand chemical exposure and handling, and the interfaces/over-molds that secure the assembly.

Considering that, here is where TPU commonly appears in scope constructions:

- The outer jacket of the insertion tube: In this context, the primary sheath, adjusted to a particular durometer, works in conjunction with the braid/coil to establish a harmony between torque fidelity and flexibility.

- Distal shaft segments and soft tips: Flexible TPU formulations help to promote soft contact and smooth transitions at the distal third.

- Strain reliefs and boots (proximal and distal): TPU over-molds are used here to manage the bend radius and cable exits, while also preventing cracking.

- Ergonomic over-molds, handle grips, and control bodies: These employ tactile TPU over a structural core for secure handling and mar resistance. When higher physical properties and chemical resistance are required, rigid TPU can serve as a polycarbonate replacement for the entire molded control section.

- Accessory/supplementary tubing: TPU is applicable in situations where there is a requirement for moderate lubrication, and bondability is crucial.

- Light-guide/cable jackets: TPU sheathing can provide excellent resistance to abrasion while ensuring flexible performance throughout an extended service life.

What OEM choices are telling us

These choices demonstrate the practicality of aligning materials with duty cycles and assessing them based on clinicians' experiences. Using the right polymer for a device can streamline the design, reduce cost per procedure, or replace fluorinated chemistry where the configuration permits. Furthermore, selecting grades with in-region availability, medical-grade support, and processing flexibility can mitigate risk for device manufacture and ensure scalability of a device.

Due to increasingly complex and multifunctional endoscopes, TPU frequently appears in concert with other specialized polymers. Devices integrating multiple polymer chemistries are complicated, and it's important to discuss material selection early with a medical-grade materials specialist. This ensures that the recommended grade meets the required performance, quality, processability, and bondability for a device design.

By doing so, you will meet the requirements of the field: endoscopes that precisely reach their targets, function reliably, and feel at home in a clinician’s hand.

About the author: Olivia Taliaferro is New Business Development Manager, Medical Polymers at The Lubrizol Corporation.Latest from Today's Medical Developments

- Hypertherm accepting applications for educational grant program

- Making workholding work for you

- Norman Noble offers medical implant engineering design services

- Lubrizol launches new medical-grade TPU material

- Medical device manufacturers embrace automated quality management

- High-performance hydrophilic coating solution

- Enercon highlights end-to-end electronics capabilities for FDA-regulated medical devices

- SABIC unveils new specialty materials for medical applications