Irvine, California – Walk around the shop and take a hard look at existing CNC equipment and processes. Could you be doing better? Could you be doing more with what you already have? The short answer is absolutely.

Campbell Engineering in Lake Forest, California, carved out a niche in high-precision, low-volume milling – particularly aluminum components for medical lasers and surgical instruments. Stepping up to the demands of tight tolerances and complex shapes, Campbell Engineering built a reputation for having high standards of quality and customer service while delivering parts on time.

A new year's 5-axis resolution

Seeking to grow the business into higher volumes of production without sacrificing precision, Campbell Engineering chose to invest in a high-performance horizontal machining center (HMC) to complement to their existing vertical machining centers (VMCs).

By the end of 2014, their new Makino a51 HMC had been steadily producing parts for one year when James (Jay) Campbell, owner and CEO of Campbell Engineering, knew that 2015 was the year to invest in a second HMC. And this time he decided to equip it from the start with a 5-axis system from KME CNC.

“When I first saw the KME 5-axis tombstones, I thought ‘What a nice fit’. It’s a new company, a new product, a new way of workholding. I hadn’t seen anything like it,” Campbell comments.

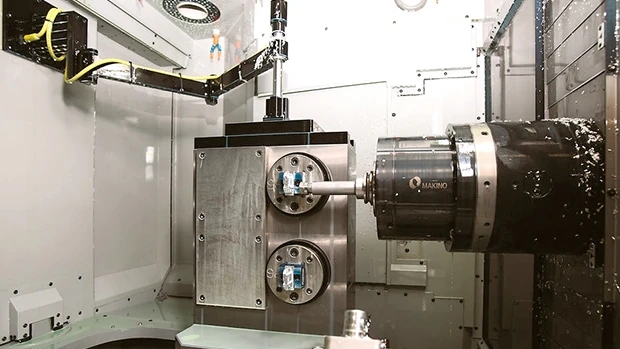

A second a51 HMC and two new KME 5-axis tombstones were delivered within six weeks of each other at the beginning of 2015. Campbell chose the standard configuration of four 5-axis drives per tombstone, two on each side. Custom setups from KME CNC can accommodate up to 12 drives per tombstone. Both 5-axis tombstones were installed on the a51, allowing the complete machining of eight workpieces at a time.

“KME fits in well with our philosophy of bringing in only the best equipment. Our Makino's are superior to other machines we considered, so our workholding equipment has to be just as good or better. That’s why we chose KME, that’s why we use Raptor vises and why we installed a built-in probing system. To hold a tolerance down to 0.0005", you have to have top notch equipment. To hold those tolerances, the less handling the better,” Campbell states.

The new 5-axis system was in full production by March and April.

“Our biggest hurdle wasn’t the equipment. Installation was plug-and-play for the most part and took about two to three days. For us, the hurdle was thinking of all the positioning possibilities,” Campbell says. “Once we overcame the mental gymnastics of how best to position parts, we were able to combine operations and improve quality, since the products we are making require five to eight operations and a true position of 0.001".”

“For the future, we would love to outfit our other a51 with a few more KME’s as soon as our backlog justifies it.”

To see Campbell Engineering's 5-axis capabilities, visit www.campbellcnc.com/5-axis-machining.

Source: KME CNC 5 Axis Systems

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025