Livonia, Michigan – In the rapidly expanding marketplace that is metal additive manufacturing (AM), it is said there are thousands of machines in place with many thousands more users struggling for success printing parts. With nearly 12 years of metal AM experience, Linear AMS is strengthening the metal AM supply chain with an innovative online tool it calls Rapid Quote – an interactive service permitting users to upload 3D CAD models, explore design iterations, and build cost models, with the assistance of the country’s leading 3D printing service bureau.

Real-time ROI

Uploading CAD model to Linear AMS through Rapid Quote not only connects users directly to the country’s most experienced metal AM service bureau, but allows users to adjust models as much as needed with automated and accurate cost quotes for each iteration, all without going back and forth with a sales rep. Problem areas are identified and options are suggested quickly, speeding rework. Configuring all the alternatives required with cost information for each greatly expands options and can save hours if not days in eliminating guesswork.

The potential for cost savings and process improvement are significant. Rapid Quote allows potential customers all the independence they want with the ability to tap into Linear’s expertise at any point in the process.

“Metal additive manufacturing is not only tearing up the rule book where design is concerned, it is remaking the supply chain by bringing on-demand manufacturing closer to everyday reality,” says founder and Linear AMS Vice President John Tenbusch. “Getting real-time quotes while at the same time improving part features, tolerances, and design for manufacturability will profoundly change and improve customer businesses.”

The ability to highlight any causes for concern on the CAD model allows considering a number of design choices all before production begins. That the same digital CAD file powers the Linear AMS metal AM equipment streamlines design through production, including process traceability and even material selection.

“Add our capacity and experience, and the quote becomes much more reliable and the process that much more efficient,” Tenbusch adds.

Linear AMS: A Moog Company

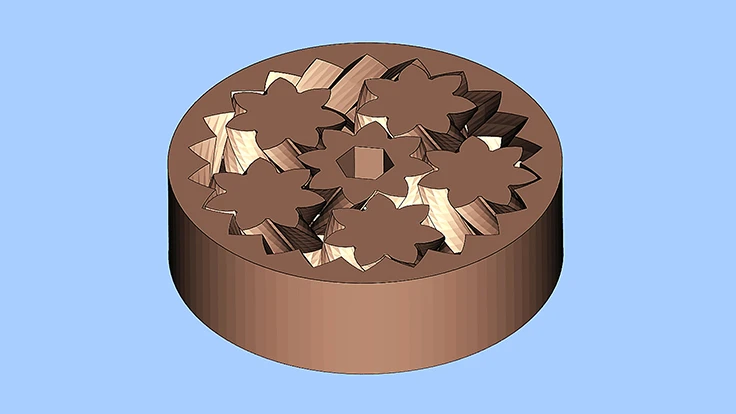

Founded in 2003, Linear AMS leverages pioneering metal additive manufacturing expertise and significant traditional subtractive manufacturing knowledge to surpass customer expectations producing prototypes, pre-production, production parts, tooling/injection molds, and conformal cooling inserts. With solid engineering and technical support from majority owner Moog Inc., black-box design, process controls, material qualifications, and inspection standards are resulting in next-generation applications for aircraft, space and defense, oil and gas, energy, industrial components, automotive, medical/dental, and consumer packaged goods. Understanding and sharing our customers’ needs for innovative solutions backed by reliable, on-time delivery, our experience in metal AM, our production-level capacity, and our problem-solving capabilities create a customer-support culture second to none. Put our expertise to work for you.

Source: Linear AMS

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025