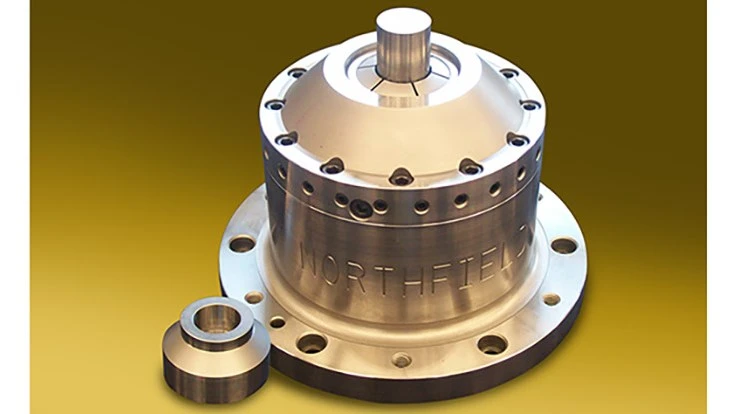

Island Park, New York – Northfield Precision Instrument Corp. engineers have designed a special gimbaling collet chuck. This chuck uses a special precision collet to grip the pitch diameter of a splined drive shaft for balancing. The collet taper is ground inside a sphere, which is then installed to the mating sphere, allowing the collet to gimbal. When a drive shaft is placed in a balance machine, it whips due to the unbalance. If the chuck holds the shaft rigid (not allowing whip), the shaft is falsely balanced with poor results. This gimbal chuck cuts the balance cycle in half with superior accuracy.

Northfield Precision Instrument designs and manufactures accurate air chucks for any lathe, boring machine, grinder, or VMC. Models include through-hole, high-speed and quick-change. Chucks are available in SAE or metric, in sizes from 3” (76mm) to 18” (457mm).

Accuracies of 0.001” to 0.00001” (0.254m) are guaranteed.

Source: Northfield Precision Instrument Corp.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025