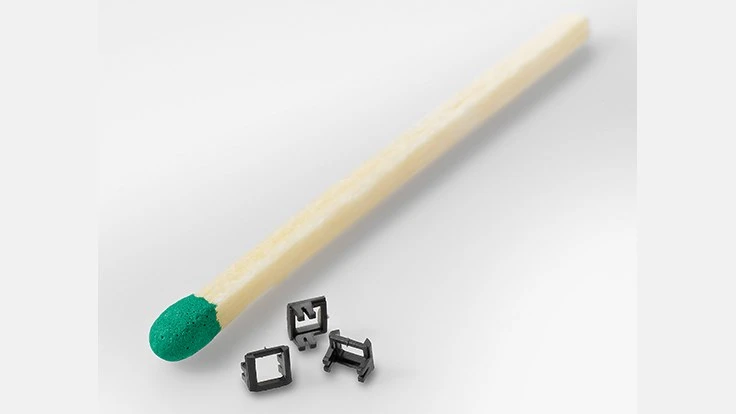

Center Conway, New Hampshire - Ceramco’s MicroPIM utilizes many of the alumina or zirconia production formulations Ceramco currently uses for its high volume manufacturing of larger components.

“The incredibly small scale of MicroPIM, requires careful adjustments to the feedstock to achieve a very low viscosity. Other than that, it is virtually the same process Ceramco has been using successfully for 30 years. Everything is just much smaller,” says Thomas Henriksen, president of Ceramco.

MicroPIM-formed ceramic components are already found in applications including, fiber-optic, ferrules, and wire bonding nozzles. Ceramics step-in when metal alloy or plastic components fail, or simply do not possess the properties demanded by the harsh environments in which they must perform. MicroPIM-formed components expand upon Ceramco’s ability to offer customers a ceramic alternative.

“Never again will I have to tell a customer, ‘the part you’re asking us to make is too small,’” Henriksen adds.

Source: Ceramco Inc.

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables