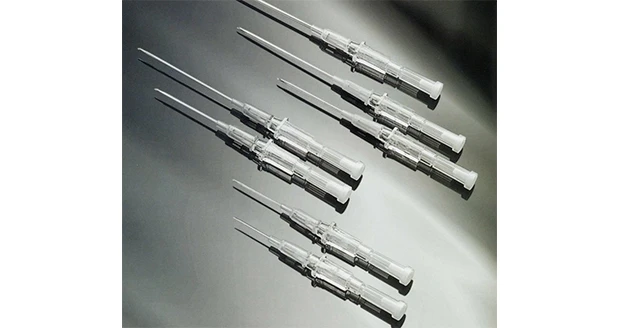

Nagoya, Japan and Santa Ana, California – Asahi Intecc, an ISO 9001/13485 certified medical device components manufacturer complete with

guidewires and microcatheters, offers fully extruded stainless or nitinol torqueable assemblies as solutions for emerging design projects.

With the acquisition of a polymer tube manufacturer for microcatheters in

2010, Asahi Intecc is a one-stop-shop for ptfe, etfe, pu, fep liners, and extrusions to save designers and commodity managers time and money, as well as improved bonding strength and lubricity.

In addition, Asahi Intecc offers extensive secondary operations, including inner etfe, ptfe liners with thin wall laser welded assembly of hypotubes, cutters, burs, micromachined parts, and housings, both laser cutting and centerless grinding services as well as laser cut hypotubes and centerless ground or swage ACTONE cable tube. Inner diameters of up to 2.5mm may be lined with PTFE.

Source: Asahi Intecc USA Inc.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025