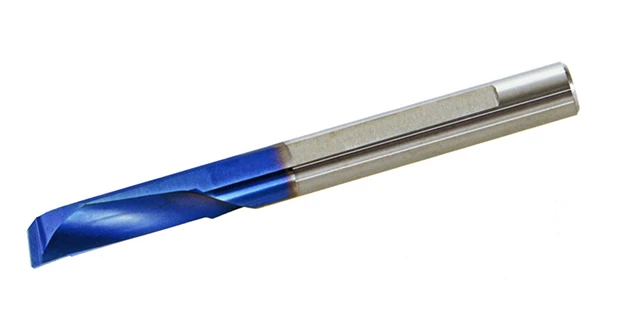

Richfield, Wisconsin – The latest addition to the Carmex Tiny Tool line – the multi-task CMR—allows users to bore, turn, face, and chamfer with a single tool. The unique cutting geometry permits machining without the need for a pilot hole, thereby saving the time and expense of an entire operation.

Designed with a vertical coolant hole and a spiral flute, the CMR continually evacuates chips out of the hole during machining.

“The new CMR Tiny Tool not only shortens machine cycle time but, thanks to the variety of operations it performs, it saves money on tooling,” according to Jeff Dei, president of Carmex USA. “Sub-micron carbide, coupled with BMK grade carbide and advanced PVD triple layer coating, improves finish and yields longer life. CMR delivers unprecedented versatility, combined with productivity and dollar savings.”

Source: Carmex Precision Tools LLC

Latest from Today's Medical Developments

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor