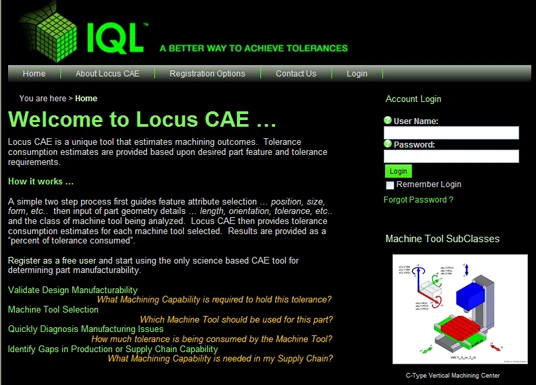

IQL (Independent Quality Labs, Inc.) introduces “LocusCAE.com” the first of a new generation of computer aided engineering (CAE) tools for predicting machining outcomes based on machine tool capability.

Precision manufacturers are challenged daily to design and troubleshoot demanding machining operations with increasingly tight tolerances, often resorting to costly iterative “make and measure” diagnostic methods or statistical process capability trials as they work to refine their manufacturing process. Processes are tweaked and offsets adjusted as production staff work to maintain process control. These approaches consume valuable production resources, extend lead times and often fail to identify the underlying “root cause”.

LocusCAE.com provides the first of its kind CAE tool with a foundation based upon the simple practical concept of a “manufacturing process error budget”. “Applying an ‘error budget’ or breaking down a manufacturing process into its components is intuitive for anyone in manufacturing,” according to IQL Vice President Michael Mariani. “What’s been missing are tools which accurately predict each component’s contribution.” LocusCAE predicts the impact of the machine tool’s capability on the process. Understanding the machine tool’s contribution significantly simplifies process design and diagnostics.

This new approach developed by IQL divides each machining operation into desired attributes and features, or Attribute Feature Pairings (AFPs). A simple example would be the location of a hole … the location & tolerance define the “desired attribute” and the hole and reference surfaces represent the “features”. LocusCAE is unique as it considers all surfaces being machined, both the hole as well as the reference surfaces, to predict the machining outcome.

LocusCAE can be used by Design Engineers to analyze part manufacturability, Production Planners and Procurement Staff to select the appropriate machining resource as well as by Manufacturing Engineers to design or troubleshoot machining operations.

IQL is a leader in the development and application of methods and tools for improving machining processes by aligning machine tool positioning capabilities with part feature tolerance requirements. The company’s technology uses machine tool behavior to diagnosis and resolve manufacturing issues related to challenging feature tolerances. With more than twenty years of experience, IQL is the preferred resource for manufacturers wishing to create and sustain “First Part Correct” manufacturing processes. For additional information, visit IQL at www.iqlinc.com.

Latest from Today's Medical Developments

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables

- The compact, complex capabilities of photochemical etching

- Moticont introduces compact, linear voice coil motor

- Manufacturing technology orders reach record high in December 2025