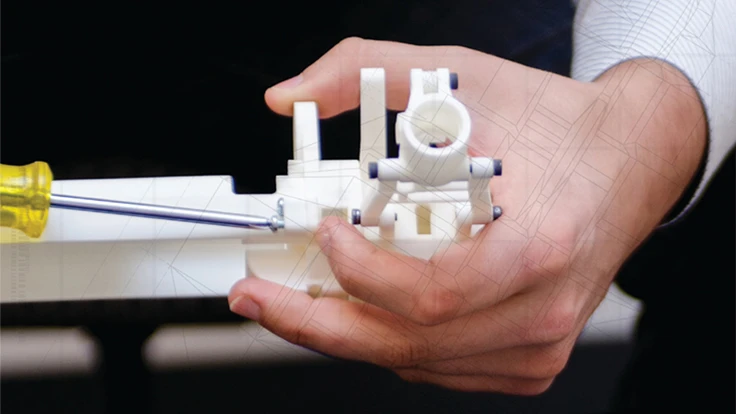

Rock Hill, South Carolina – For the past three decades, rapid prototyping has been synonymous with 3D printing. The technology has come a long way with faster printing speeds, true-to-CAD part accuracy, smoother surface finishes, and sharper resolutions. A wide variety of material options are now available from plastics to metals, and many can mimic production quality end-use products.

Compared to conventional methods, 3D printing offers several benefits in creating prototypes and models, including strengthening a product's value by compressing development cycles, reducing costs, and enhancing the final product's quality and design.

Source: 3D Systems

Latest from Today's Medical Developments

- Stryker’s flexible syndesmotic fixation device stabilizes ankle injuries

- Mergers & acquisitions news: MGS, Quantum Surgical bolster medtech portfolios

- Exchangeable-head solid carbide cutting tools

- NextDent 300 MultiJet printer delivers a “Coming of Age for Digital Dentistry” at Evolution Dental Solutions

- Get recognized for bringing manufacturing back to North America

- Adaptive Coolant Flow improves energy efficiency

- VOLTAS opens coworking space for medical device manufacturers

- MEMS accelerometer for medical implants, wearables